Company Information

Ask for more detail from the seller

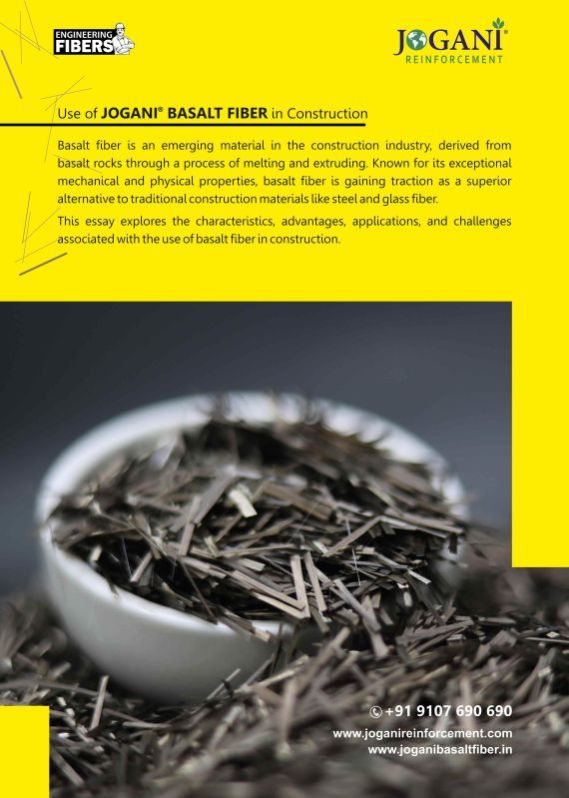

Contact SupplierJOGANI Basalt Fiber is a type of reinforcement fiber used in construction and various industrial applications. Made from basalt rock, it offers several advantages over traditional reinforcement materials. Here’s an overview of JOGANI Basalt Fiber:

JOGANI Basalt FiberDescription:

JOGANI Basalt Fiber is a high-performance reinforcement fiber derived from volcanic basalt rock. The fiber is produced by melting basalt rock and then extruding it into fine fibers. It is used to enhance the mechanical properties of construction materials, particularly concrete.

Key Features:

Material: Made from basalt rock, which is a natural, abundant, and eco-friendly resource.

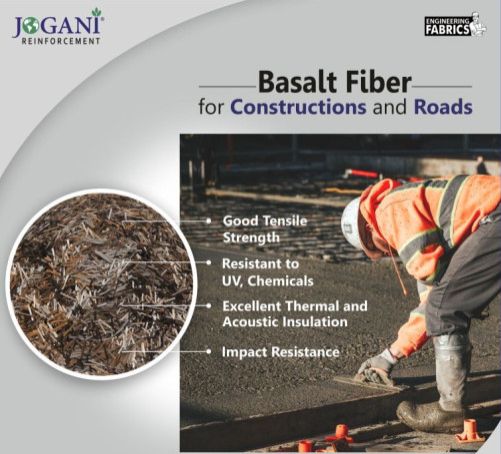

High Strength: Basalt fibers offer excellent tensile strength and impact resistance, making them effective in reinforcing construction materials.

Corrosion Resistance: Unlike steel reinforcement, basalt fibers are highly resistant to corrosion, which improves the longevity of the reinforced material.

Thermal Stability: Basalt fibers maintain their strength at high temperatures, making them suitable for applications in environments with extreme temperature variations.

Lightweight: Basalt fibers are lighter than steel fibers, which can make them easier to handle and apply.

Applications:

Concrete Reinforcement: Used in concrete to improve strength, ductility, and crack resistance, particularly in aggressive environments.

Asphalt Mixtures: Enhances the performance of asphalt by increasing its durability and resistance to deformation.

Precast Concrete Products: Suitable for use in precast elements such as panels, beams, and columns to enhance their mechanical properties.

Composite Materials: Can be used in the production of composite materials for various industrial applications, including automotive and aerospace.

Reinforced Plastics: Used in the reinforcement of plastic products for added strength and durability.

Benefits:

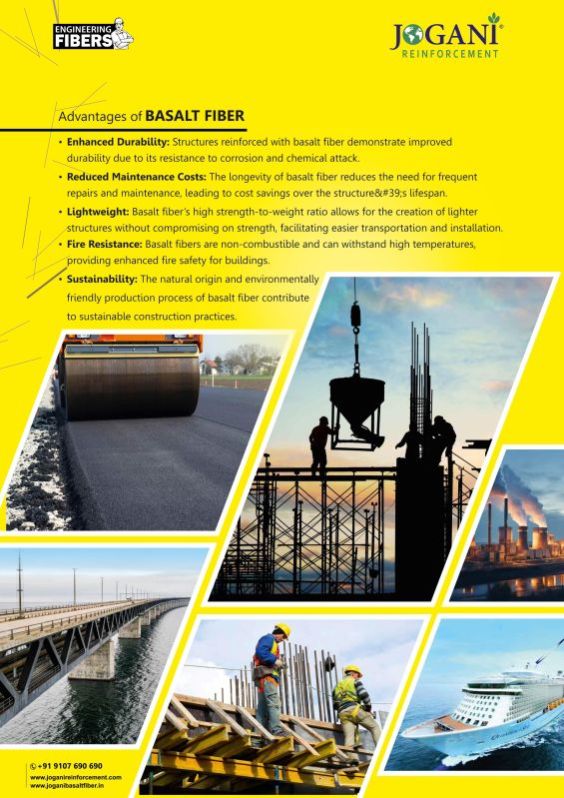

Enhanced Durability: Improves the durability and lifespan of concrete and other materials by preventing cracking and reducing wear and tear.

Corrosion Resistance: Basalt fibers do not corrode, which makes them ideal for use in environments with high moisture or chemical exposure.

Improved Mechanical Properties: Increases the tensile and flexural strength of materials, contributing to overall structural integrity.

Eco-Friendly: Basalt is a natural material that has a lower environmental impact compared to synthetic fibers.

Cost-Effective: Often more cost-effective than other high-performance fibers due to its abundant availability and manufacturing process.

Usage Instructions:

Mixing: Basalt fibers can be added to concrete or asphalt mixes during the batching process. Ensure even distribution for optimal performance.

Dosage: The amount of basalt fiber to be used will depend on the specific requirements of the project. Typical dosages range from 0.5% to 2% by weight of the binder or matrix.

Application: Follow standard procedures for mixing, pouring, and finishing the material. The fibers should be well-integrated into the matrix to achieve the desired properties.

Safety and Handling:

Protective Gear: When handling basalt fibers, it’s advisable to wear protective clothing, gloves, and masks to prevent irritation from the fine particles.

Storage: Store fibers in a dry place to prevent moisture absorption and maintain their performance characteristics.