Listing ID #1870723

Company Information

Ask for more detail from the seller

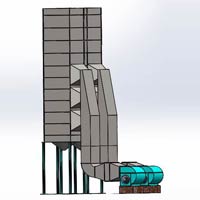

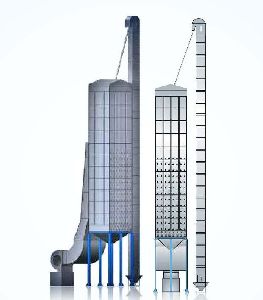

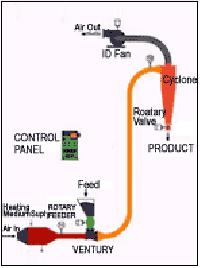

Contact SupplierIn band dryers, drying is effected by circulation of hot air through a bed of material as it is carried through the dryer. Depending upon the requirement, the drying enclosure comprises of a single chamber or is divided into a number of drying sections each including an air heater and circulating fan together with fresh air inlet and exhaust facilities. These dryers are of modular design to optimise drying efficiency by providing precise temperature control in each zone.

The range of band dryers include: single-pass, single-pass-multi-stage and multi-pass conveyorised paddle-dryer-manufacturers.html type and single pass single or multi stage rail guided moving trolley type. The paddle-dryer-manufacturers.htmls can be of flat, chain, mesh or slat type. Drying efficiency is maximised by the use of: upwards/downwards airflow, double skin insulated panels, effective sealing of dryer enclosure, even air distribution, variable speed conveyor drives and air recycle.

Feeding can be effected by means of oscillating paddle-dryer-manufacturers.html, oscillating rake, vibratory and apron feeders. Also by granulators and extruders. Special features incorporate integral or separate cooling section to suit product temperature. continuous collection of fines, explosion venting, heat recovery, exhaust air clean up, cleaning brushes, band scrapers and washers or full C.I.P. modular control panels, pre-wired for installation

Conveyorised band dryers are best suited for continuous drying of temperature sensitive and sugar containing products at low temperatures under vacuum conditions. The vacuum dryers consist of a vacuum chamber in which conveyer bands of food grade quality are arranged. The band passes over the hot plates heated internally by steam or hot water. Feed product is spread on the moving band and is dried as it moves on the hot plates. Dried product is obtained at the other end of the vacuum band dryers.

Voice Engineers is manufacturer and supplier of drying system, Band Dryer and Designer of Band Dryer

Applications :

Band Dryers are suitable for processes such as tempering, annealing, curing, preheating, paint drying, etc. and also for drying