Listing ID #6713985

Company Information

Ask for more detail from the seller

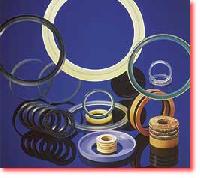

Contact SupplierDual seals are recommended for a variety of purposes that include:

All of the above are sensible reasons for using two seals in a pump, but In this paper we’ll be considering the use of dual seals as an environmental control to prevent the sealed product from either opening the seal faces, or damaging one of the seal components, the two reasons any mechanical seal ever failed.

We can use the dual seals to:

Dual seals can be of either the rotating or stationary version and can be installed in four different configurations.

The fluid that circulates between the seals is called barrier fluid if it is higher than stuffing box pressure. It is called buffer fluid if it is lower than stuffing box pressure. It can be circulated between the two seals by:

The following illustrations describe the rotating version (the spring or springs rotate with the shaft) of these dual seal configurations. You should be aware that a stationary version is also available from any of the major seal companies. You should also consider: