Listing ID #4647958

Company Information

Ask for more detail from the seller

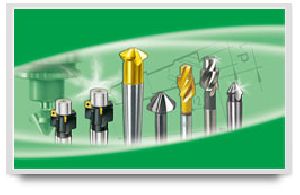

Contact SupplierThese tools, unlike the conventional back spot facing tool, are made from a single solid metal structure. The single piece construction & the other design features are such that the tool will bear all the stresses and vibrations. It produces accurately controlled back spot face dimensions.

Structure:

Working:

Advantages: