Company Information

Ask for more detail from the seller

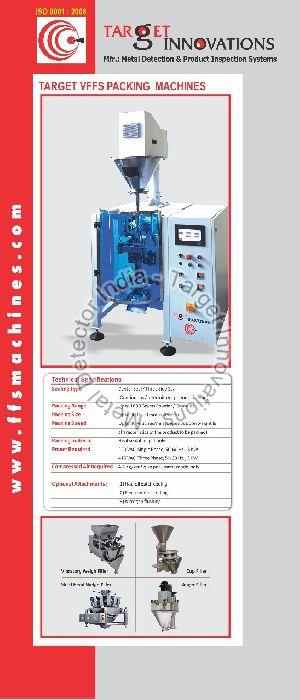

Contact SupplierWe offer Automation Packaging Machine (AP-1200P) which ensures efficient and cost-effective methods of packaging products in pouches. Pouches are not known to repeatable shapes and footprints, so they require advanced machine to sealing such as our Automation Packaging Machine. The Automation Packaging Machine is fast and efficient and easy to operate providing secondary packaging / end of line automation solutions.

Main Frame