Listing ID #3783135

Company Information

Ask for more detail from the seller

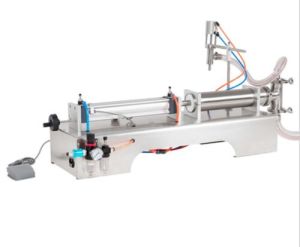

Contact SupplierDYNAMIC ENTERPRISES" is the pioneers in the manufacturing and exporting of Automatic Bottle Filling Machine. Based on the efficiency factor of Automatic Bottle Filling Machines, we are statured as the prime manufacturer and supplier of Automatic Bottle Filling Machine. Usage To hold and index the bottles, a frame structure, a vibratory cap feeder, and drive mechanism Filling liquids in bottles on continuous running S.S. Slat conveyor. Accomplished with Input and output conveyors Flower wheel (Turret) arrangement Separate panel box Control switches Technical specifications Bottles are collected and moved to the filling station from the conveyor by a turret wheel Electricity required: 1 Phase,220VAC,50Hz, 1.5 KWH Filling station, filling of required volume is done accurately Output: 20 containers per Minute The turret holds and indexes the filled bottles to a cap placing station Fill range 25ml to 100ml Vibratory cap feeder controls the orientation of the caps and feeds to a chute, which leads to the capping station Labor required : 1 semi-skilled operator When the bottle comes to the station, each bottle is placed by cap and ready to tighten Separate control Panel with control switches During the next indexing, tightening of caps to the required strength occurs Works on volumetric principle and used for filling liquids in bottles on continuous running S.S. Slat conveyor Tightening station can either screw capping or press capping according to the requirement of customer Single or Multiple bottles can be filled at a time with predetermined volume After tightening, the flower wheel indexes and the capped bottles carried to an outlet conveyor for final packing Fixing appropriate size of the syringes can fill different capacity bottles in a particular time Clutch Brake assisted filling for sudden start and stop A specially designed synchronized Mechanical movement with the conveyor system and bottle-indexing mechanism ensures smooth running of the machine No-container-No fill-No-cap facility A NO BOTTLE NO mechanism prevents spillage of liquid when the continuous flow of bottle is not available Cap feeding by Bowl feeder/vibratory feeder The unit is designed to fill aseptic liquids with precise accuracy and can give output of 40-60 bottles/minute for double head depending on quality of bottle and fill sizes Cap pressing/cap tightening at separate station