Listing ID #735773

Company Information

Ask for more detail from the seller

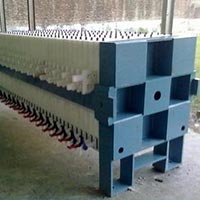

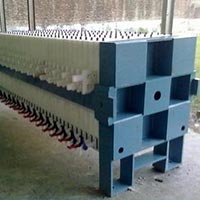

Contact SupplierThe highly efficient automated advanced filter press we manufacture is equipped with features that make the range excellent for granites, marble & ceramic industries, gypsum, crystalline salts, pigments, dry precipitates, sludge generated from galvanizing plants containing chromium, zinc, aluminum, copper, nickel or cadmium, and many other applications.

Automatic filter press has the following components:

plate shifting & plate shaker for auto cake discharge

plc based electrical control panel

pneumatically operated control valves

flow sensor and hydraulically operated door drip tray

how it works:

a push button initiates the filtration process. Slurry is pumped into all chambers and cakes are formed as filtration begins to flow

the end of filtration phase is automated by flow meter which is located on filtrate discharge pipe

the flow meter indicates the minimum flow rate of filtrate which is strictly related to the end of a cycle, the opening of filter press and the discharging phase

a plate vibrating device during the discharge phase ensures 100 pct release of the cake

a plc controls the phases and cycle times for all the filter press functions including operation of the ancillary equipment

use of the most modern and advanced systems for operator protection and safety

special features

zero downtime

saves 96 % of labour cost

achieve final solid consistency at outlet upto 75%

short cycle time: 8 to 30 minutes

less capital expenditure : filter press & dryer can be planned smaller

lower pollution control cost

increased product yield

improved process economy

reduced space requirement

fully automatic cycle

manual mode option

plc based controls

upto 1500 x 1500mm plate size

vibration system for cake drop

drip tray system.