Listing ID #3832760

Company Information

Ask for more detail from the seller

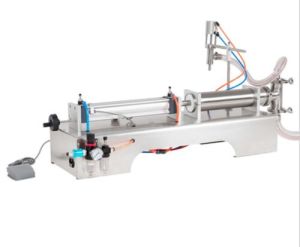

Contact SupplierContainers moving on SS Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system. The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards from bottom level of bottle towards neck during filling. The Digital filling system arrangement is standard features of the machine. The motor for filling is servo drive and conveyor drive is AC Motor with synchronized variable AC Frequency Drive. PLC Controller provided to set fill volume, speed of conveyor and set fill timing this means fill size can be easily set.

Salient Features:

| Model | DLF-50-2H | DLF-100-4H | |

| Output | 20-40 Bottles/Min (Depend on Fill Volume) | 40-60 Bottles/Min (Depend on Fill Volume) | |

| Electrical Characteristics | 3.5 HP, 440 Volts,3 Phase, 50 Hz, 4 Wire System | 5.5 HP, 440 Volts,3 Phase, 50 Hz, 4 Wire System | |

| Direction of Movement | Left to Right | Left to Right | |

| Number of Head/Nozzles | 2 Head | 4 Head | |

| Fill Size | 10ml to 1000ml | 10ml to 1000ml | |

| Height of Conveyor | 860mm to 910mm Adjustable | ||

| Overall Dimension | 1600mm L X 1110mm W X 1830mm H | ||

| Air Pressure | 6 Bar Pressure @ 0.5 CFM | ||