Listing ID #4913622

Company Information

Ask for more detail from the seller

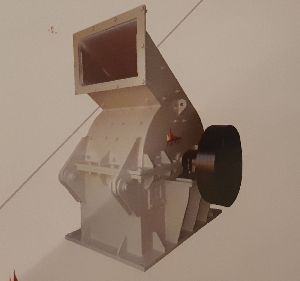

Contact SupplierWe offer customers automatic suction hammer mill that comes in capacity ranging from 6 H.P. To 85 H.P. Available under the brand name 'Techno Wings' these automatic machines maintain due to continuity flow through automatic suction through motor. Further, the ampere of motor does not fluctuate, hence increasing the working capacity of machine. The basic principle is straight forward. A hammer mill is essentially a steel drum containing a horizontal rotating shaft or drum on which hammers / blade are mounted. The hammers are free to swing on the ends of the cross, or fixed to the central rotor. The rotor is spun at a high speed inside the drum while material is fed into a feed hopper. The material is impacted by the hammer bars / blade and is thereby shredded and expelled through screens in the drum of a selected size.

Key features of auto suction hammer millThe materials to be ground into the crushing chamber of auto suction hammer mill from feed hopper by gravity or through an automatic rotary feeder the carbides blades inside the crushing chamber accelerate the material to a very high speed to the toothed liner placed at the upper half of the crushing chamber. Shearing pulverises the material. The ground materials are continuously sucked by a centrifugal blower through screens placed at the bottom periphery of the crushing chamber and conveyed through a pipe into the cyclone dust collector for bagging. Excess air filtered through an air classifier. Particle size varied using screens with different size holes.

Standard accessories of auto suction hammer millHammer mills are exclusively meant for the grinding of turmeric, red chili, cumin, coriander, mango powder, sugar, wheat for ladu, salt, coffee, ayurvedic / homeopathic medicines herbs, roots, leaves, bark, dry fish, cattle and poultry feeds, food colors and so on so forth at large scale basis.

Construction of auto suction hammer millRotary feeder is supplied with gear box. Hammer mill made from heavy duty mild steel fabricated body. Grinding chamber lined with serrated wear plates, which protects the body from wear and tear. Grinding is done by a set of swinging blades or hammers on a balanced rotor. A screen classifier forms the lower half of the grinding chamber. Blower is driven on a separate shaft with the help of a 'v' belts & separate motor.