Listing ID #2184436

Company Information

Ask for more detail from the seller

Contact SupplierMixer-Settler Extraction Unit

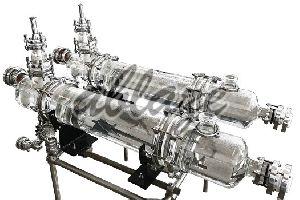

The Mixer-settler system is fabricated and assembled in a compact modular design. The mixer as well as the settler are both integrated together instead of being separate entities. This allows the system to be compact and ideal for laboratory and R&D usage. A single stage of Mixer-Settler consists of a mixing zone and settler decanting zone connected to each other through a Weir zone.

A brief description of the zones is as follows :

Mixing System

The Laboratory mixer consists of a special glass / SS (as per choice) mixing zone, suitable high-speed agitator and a variable speed drive. Besides providing an intimate dispersion the stirrer provides the necessary pumping action. This eliminates the need for external pumps and ensures a large interfacial area for mass transfer. The energy required to produce this dispersion will depend very much on the characteristics of the material and the system used (interfacial tension, viscosity, flow rates, etc).

Between the mixing and separation zones, a weir is incorporated to prevent back mixing taking place and maintains the level of liquid in the mixing zone. Besides this, it also acts as a baffle to dampen the flow of liquid into the decanter (settler) for enhancing efficient phase separation.

Settling System

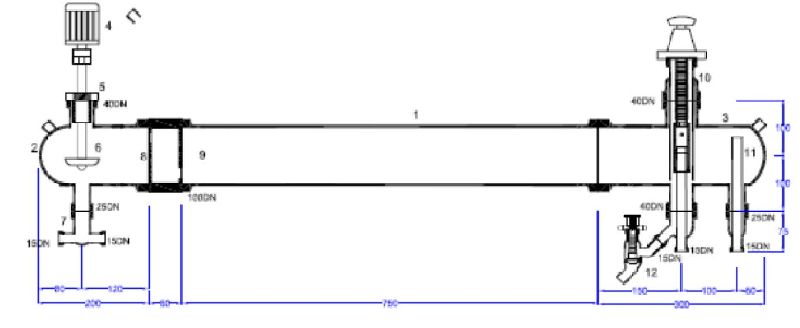

The settler comprises a horizontal cylindrical pipe which depending upon size may be one or more pipe sections. From the settler, the outlet of the heavy phase, is controlled by an overflow valve. The design of the settler will be influenced by the throughput of both phases and the material physical properties (density difference, viscosity, interfacial tension etc).

Multi-Staging Mixer-Settlers

Different stages can be connected to each other and the interconnecting pipelines can be done as per your required flow logic. The whole assembly would be controlled through a control panel consisting of suitable circuit breaker MCBs, Relays, digital controllers etc.