Company Information

Ask for more detail from the seller

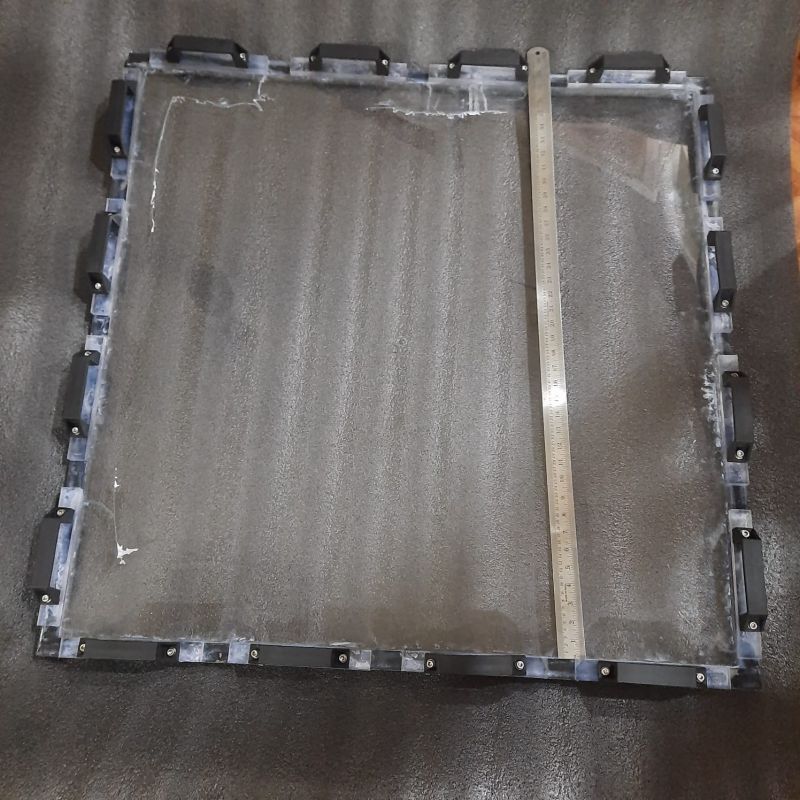

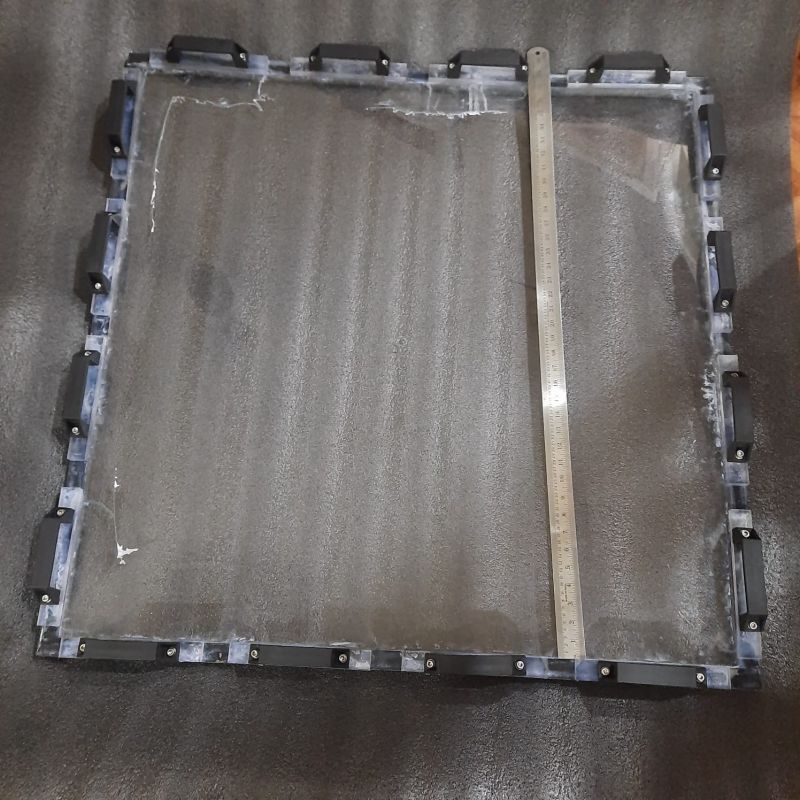

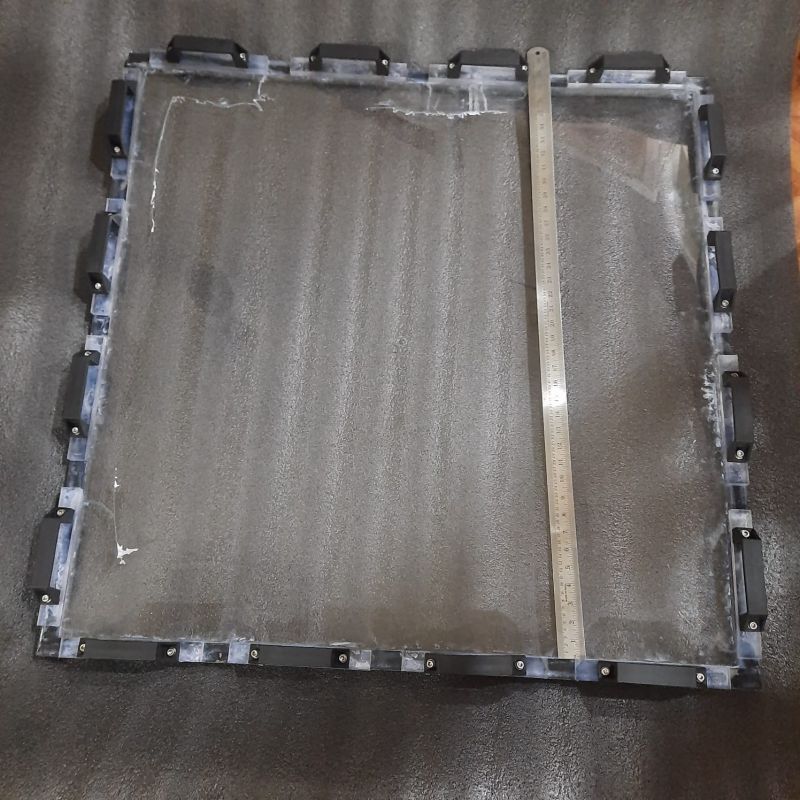

Contact SupplierFlexible Transparent semi Flat -Angular Vacuum box

for testing butt welds on Sea Chest in Large ships

The Angular Vacuum Weld Leak Test Box for Sea Chest designed by Burhani Engineering Technology is a crucial tool for ensuring the integrity and reliability of sea chest systems onboard ships. Sea chests serve as intake reservoirs for piping systems that draw raw water for various purposes such as cooling systems, fire-fighting systems, and ballast operations. These chests are typically equipped with removable gratings and baffle plates to mitigate the effects of vessel speed and sea conditions.

The intake size of sea chests can vary significantly, ranging from less than 10 cm² to several square meters, depending on the requirements of the vessel and its systems. When a ship is sailing in open seas with a moderate or deep draft, the low sea chest is commonly used. This configuration helps maintain the appropriate intake pressure by allowing sufficient water to enter the suction lines, even during rolling motions of the vessel.

Using the high sea chest in open sea conditions can lead to potential issues such as a drop in main seawater pressure. This occurs because less water may enter the suction lines due to the higher position of the sea chest, which can result in inadequate flow rates for essential systems relying on seawater.

The Angular Vacuum Weld Leak Test Box plays a vital role in ensuring that the welds and joints of the sea chest system are free from leaks. Vacuum testing is a widely accepted method for detecting leaks in welded and sealed structures. The test box is designed to create a vacuum within the sea chest system, allowing technicians to identify any areas where air ingress occurs, indicating potential leaks in the welds or seals.

Burhani Engineering Technology's expertise in designing and manufacturing such specialized equipment underscores its commitment to ensuring the safety and efficiency of maritime operations. By employing advanced testing methodologies like vacuum leak testing, ship operators can maintain the integrity of critical systems and mitigate the risks associated with leaks or structural failures in sea chest installations.