Listing ID #4262209

Company Information

Ask for more detail from the seller

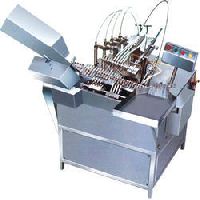

Contact SupplierUser friendly reliable and safe solution for the high speed filling needs. Dosing syringes driven by separate brush-less motor. Ampoule sampling unit without stopping the machine. Possibility to memorize various parameters of different ampoule sizes

Salient features:

1. Self centering grippers for the transport of all ampoule diameter within the size range without the need to change.

2. Ampoule neck centering during gas flushing and filling 3. Possibility of gas flushing before, during and after the filling.

4. AISI 316L dosing syringes without gaskets.

5. Drip free adjustment for media of different viscosity.

6. Possibility of direct connection to sterilizing tunnel.

7. No ampoule no filling function.

8. Fully accessibility allows easy maintenance.

9. Fast change-over due to extremely limited number of parts to be replaced.

10 Individual micro metric adjustment of the syringes.

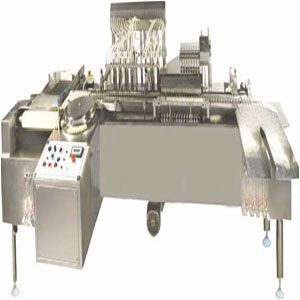

Other features

1. Dosing syringes driven by separate brush-less motors 2. Ampoules sampling unit without stopping the machines

3. Possibility to memorize various parameters of different ampoule size

4. The ampoule is transported by in-feed conveyor in feed scroll and ampoule transfer into transport rack

5. 8 Ampoules are advanced per machine stroke

6. Centering of ampoules necks during gas flushing and liquid filling

7. Elimination of burned off ampoules tips by clipper and ejection into separate container

8. Discharge of filled and sealed ampoules into discharge tray.