Listing ID #3812878

Company Information

Ask for more detail from the seller

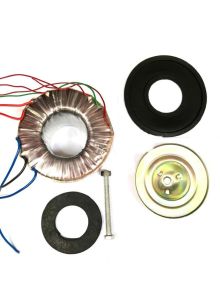

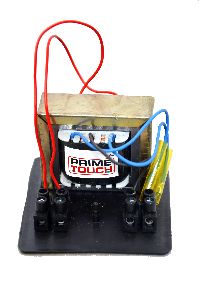

Contact SupplierKOTSONS has set up state of the art amorphous metal core transformer manufacturing facility by importing the latest amorphous metal cores manufacturing equipment. This plant has the latest equipment in India to produce energy efficient amorphous metal transformer cores that are annealed under absolute inert atmosphere to get at most lower losses thereby enhancing the energy savings in comparison with the similar manufacturing facilities in India.

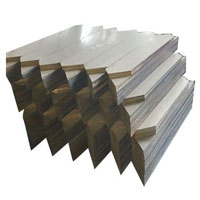

Amorphous metal exhibits a unique random molecular structure unlike the rigid grain structure of the silicon steel. This, in turn, enables easy magnetization & demagnetization, thereby reducing hysteresis loss. Further processing of amorphous metal in very thin lamination (approximately 1/10th of silicon steel lamination thickness) enables significant reduction in eddy current losses.

Advantages of Amorphous Metal Transformers over Transformers with CRGO Silicon Steel :

1. The thickness of Amorphous Metal is 0.025 mm against CRGO silicon sheet steel thickness 0.23-0.3 mm. Lesser in thickness in sheet results in lower eddy current loss

2. Random molecular structure of amorphous metal causes less friction than CRGO when a magnetic field is applied. This allows easy magnetization and demagnetization significantly lowers hysteresis losses, thus amorphous core significantly reduces core losses which is about 65-75%

3. Saves energy and therefore reduces greenhouse gases and other pollution

4. Excellent option to reduce distribution losses and improve efficiency

5. Superior electrical performance under harmonic condition. Possible to improve power quality and mitigate harmonics

6. Lower temperature rise, slower deterioration of insulations and hence longer life

7. Increase in use of power electronics has resulted in considerable amount of higher harmonics distortion in electrical power system. Higher frequency harmonics lead to increase in transformer core losses whereas amorphous alloy provides lower loss under high frequency

8. Easy for repair and replacement of coils