Listing ID #4882434

Company Information

Ask for more detail from the seller

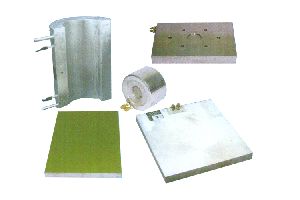

Contact SupplierThe liquid cooling function of the Cast Band Heater is of primary importance in maintaining the proper temperature of the barrel in the extrusion process.Extrusion machines differ from injection molding machines in that they often require heating and cooling. Cooling is required on extruder barrels to offset heat generated by frictional shear as the screw pump pushes plastic melt through the barrel and die head.

The Cast Band type comes with Water Cooling system & without Water cooling system. The Cast Band Heaters uses aluminum, an excellent heat conductor, to deliver a very uniform heat pattern on the barrel.

All Aluminum Cast Band Heaters are customized. The Tubular Heating element is embedded in the Aluminum Cast Band Heater & machining is to be done to get the required size.

High Thermal Conductivity provides uniform temperature. The main application of these heaters is in the Extruders.