Listing ID #7126061

Company Information

Ask for more detail from the seller

Contact SupplierFor decades, Aluminum Sulphate, popularly known as alum has been used as a raw material in water treatment industry. Easy availability and large molecular size makes it an excellent flocculent for treatment of both potable water and industrial waste water. Alum also finds use in a diversity of other areas including construction products, oil / fat processing and paper manufacturing. It has many trade names such as Ferric Alum and Non -Ferric Alum, "pearl alum", "pickle alum", "papermakers' alum" etc

Process Description

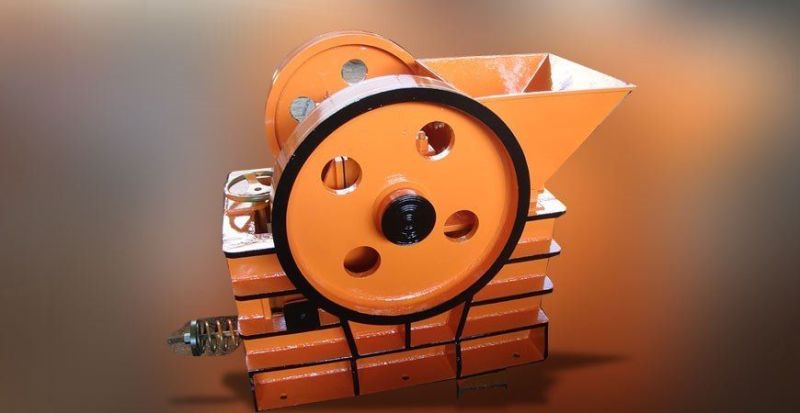

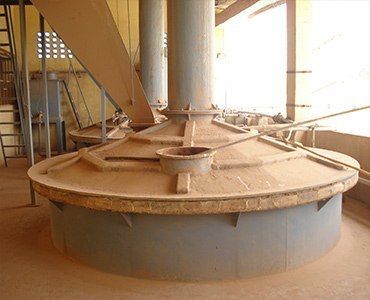

The raw material bauxite lumps are crushed to - 15 mm size in a Crusher and ground fine 90% passing through 100 mesh in a ball mill. The reactor is lead and Acid & heat resistant brick lined. The acid is diluted to 65-70% and bauxite powder is added slowly to neutralize the acid completely. As the reaction is over, the resultant solution is diluted to a fixed gravity with water and coagulant is added to precipitate the colloidal particles. The material is allowed to settle in settling tanks. The supernetant liquid is separated and evaporated with steam coils in evaporators. As the liquid achievers fixed gravity it is discharged in the moulds to make slabs. If the balls are to be manufactured, the spray technology is applied.

Some of the major components of Alum Plants are

We offer complete Alum Production Plant for crystalline and liquid aluminum Sulphate. These plants can be custom engineered as per the demands of the clients. We also offer excellent technical support and after-sales services for the installed plants.

Established in the year 2019, we at Fitzer Incorporation are one of the most renowned and reputed manufacturers, suppliers, and exporters of industrial equipment. We proficiently deal in Heat Exchangers, Heating Process Equipment, Cooling Process Equipment, Desiccant Dehumidifier, IQF Tunnel Freezer, Cold Storage Room, Convection Recuperator, Pressure Vessels, Storage Tanks, and Thermal Energy Storage systems. All of our products are manufactured and designed as per the global standard such as API, ASME, IBR, TEMA, and ASHRAE.

We have established world-class transportation equipped with advanced and newest technology machines that assists us in organizing the products with dimensionally accurate, extremely efficient, highly durable, corrosion-resistant, and strong construction. Moreover, with the highly demanded items, we give properly planned fabrication-erection services for industrial plants by offering system designs, fixing, and after-sales services.

We have appointed a team of professionals and well-trained experts who are aimed to create machines to manufacture products from the best quality raw materials following the best industry terms and norms.

Our team of quality controllers performs a series of tests to inspect the overall quality and operations of the products.

Fitzer Incorporation is working under the able motivation and guidance of Mr. Siddhi Chavan. Since our beginning, we have followed the policy of blending price and quality for offering the best possible items to valuable customers. We aim to increase our business shortly while keeping up our striking track record.