Listing ID #323299

Company Information

Ask for more detail from the seller

Contact Supplierwhat is akar dynamic bio-reactor (adbr) system?

conventional method of treating sewage wastewater is called extended aeration or aerobic treatment. in this type of treatment; after pre-treatment, in which coarse particles, grit, oil and grease are removed; oxygen is dissolved into wastewater through a process called aeration. the objective of dissolving oxygen into wastewater is to ensure that bacteria in wastewater survive and proliferate. basically wastewater treatment is generally a bacteriological process and the most critical part i.e. cleaning the wastewater is done predominantly by bacteria. in principle same principle is also applied in akar adbr systems but with a slight difference.

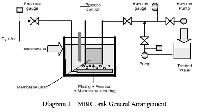

in the conventional systems, aeration is done in a water basin in uncontrolled manner. in akar adbr system, aeration is carried out in controlled condition in the presence of media. this process is also known as moving bed bio-reactor system or in short mbbr.

why adbr systems?

the “adbr” system has so many advantages over the conventional bio-reaction processes that it is very safe to say that "the adbr system is a unique and revolutionary system.

akar manufactures and markets dynamic bio-reactor waste water treatment packaged plants of different capacities starting from 20 kld (kilo litres per day) up to one mld (million litres per day) in the mini and midi range. for higher capacities please refer the inquiry to akar's office at the address given in this leaflet.

1. no foul smell - plant is fully enclosed.

2. treatment process retention time reduced by more than 60%.

3. hence space and energy saving of more than 60 %.

4. almost ready for immediate installation.

5. easily transportable. mounted on skid.

6. can be mounted on trailer (if required).

7. no major civil concrete works required at site.

8. saving on piping works requirement at site.

9. lockable from front. ( if required )

what is there in the adbr system?

process flow chart

process description:

akar dynamic bio-reactor systems "the adbr systems" are radically different in principle and operation in comparison to other systems. normal biological waste water treatment is done traditionally by suspended growth mode (e.g. activated sludge and extended aeration processes)or attached growth mode (trickling filters – rotating biological contactors). the technology adopted in adbr is combination of both which affords higher mlss concentration. in adbr systems fast bio-reaction takes place. there are two compartments. the first compartment contains dynamic “bio-reaction” media. the media has a unique property of having high area for a given volume. the media is typically designed and manufactured for this application. the second compartment is the sludge separation compartment. unique feature of this system is to use media, which is constantly in suspension. these media components are floating and are kept in circular motion by air action directed at them. in adbr systems, bio-film gets very high oxygen transfer, thus saving energy. it is safe to assume that as compared to a conventional extended aeration system, adbr bio-reactor occupies 65% less space and offers more than 65% saving in power consumption. due to exceptionally low retention time, the reactions are very fast which make “the adbr systems” very compact. the clients recover cost of equipment within less than three years as compared to the conventional aerobic systems. in the conventional systems, pockets of anaerobic patches are formed on media. such patches are indicative of restricted supply of oxygen to the reaction area causing degradation of the biological process. in "the adbr systems", the media is constantly in contact with oxygen. there are no dark patches as oxygen transfer is highly efficient. a high-speed settler tank is provided in which the sediments, being heavier, settle down leaving supernatant water to flow out from the top. this lamella settler tank provides large settlement surface area. thus clarification is achieved in the shortest possible time.

note : in case larger systems are required, two or more systems could be used in parallel. in case of large condominiums, systems could be provided for a group. systems could also be built at site using tanks in rcc or brick masonry construction. this would however necessitate considerable work at site.

model no. @ adbr 50 adbr 100 adbr 150 adbr 200 adbr 250 adbr 300 adbr 400 adbr 500 adbr 600

capacity (in m3 /day or kld 50 100 150 200 250 300 400 500 600

suitable for population of 350 670 1000 1350 1670 2000 2700 3400 4000

area required in sq. meters. for adbr 7 14 18 22 24 27 54 60 68

total area required in sq. mtrs. * 40 60 90 120 180 220 280 300 400

electrical power required of 440 v 3 phase, 50 hz. ** 6 8 10 12 15 18 20.0 26.0 26.0

@ when designed at a maximum bod of 300 mg/ ltr.

* total area means area required for adbr plus civil works, electrical works and for other infrastructure activities.

** power and area requirement includes tertiary treatment.

in case larger systems are required, 2 or more systems could be used in parallel. in case of large condominiums, systems could be provided for a group. systems could also be built at site using tanks in rcc or brick masonry construction. this would however necessitate considerable work at site.

working of adbr system:

incoming sewage is collected in an incoming sump (outside adbr) which has a screen fixed at the entry of sump. a cat ladder and manhole are provided to clean the screen and enter the sump when required. a sewage pump is provided as a part of the adbr to transport liquid to the bio-reactor system from the incoming sump located outside adbr. this pump can be submersible or centrifugal, depending on application. the pump operates through a level controller for ensuring automatic operation. once in the bio-reactor, the sewage undergoes aeration and subsequent attached growth.

aeration is done through a blower mounted within the adbr. extensive aeration coupled with slow circular movement of high surfaced media pushed by air flow ensures that bacteria form large settlements on the media. this settlement is exposed to oxygen constantly and bacteria are never devoid of oxygen. this results in increased biological process due to presence of two systems namely, aerobic suspended growth and attached growth. the reactor also enhances the degradation of organic matter present in the sewage. it is the organic matter in sewage that gives rise to bod. this results in high efficiency of treatment. from bio-reaction section the sewage is transferred to lamella plate type settler in which all sludge (bacteria along with organic matter) is separated from sewage and only traces are discharged with sewage within limits of the pollution control authority norms.

the treated sewage is chlorinated and transferred to treated water tank (outside adbr). treated water pump diverts water to horticulture application or disposal as desired by client. sludge is pumped to filter press or hydro cyclone (optional) for conversion to sludge cakes or concentrated sludge which is dried and is made available in solid form for easy disposal. the sludge cakes may be used as manure. thus this system offers complete environment friendly solution to pollution problems.

the pre-fabricated adbr is a completely enclosed system with pumps, blower, panel, piping etc. housed in a pre-fabricated unit. the system is pleasing in appearance and completely enclosed like a container. the system could also be transferred to another location by container if so desired and provides flexibility of location.

the adbr is a completely enclosed system with pumps, blower, panel, piping etc. housed in a pre-fabricated unit. the system is pleasing in appearance and completely enclosed like a container. the system could also be transferred to another location by container if so desired and provides flexibility of location.

adbr in different configurations

akar adbr systems are packaged systems. however, they are also available in containerized configurations. there are many containerized adbr systems in operation in many parts of the world. a picture of a standard mini model of adbr system is given below.

adbr systems are available in other configurations also. for example adbr system can also be configured in civil construction tanks. here through akar research and development, different parameters are established to set up adbr system with civil construction tanks and in case capacities are 1000 kld or one mld. an internal view of the plant room and an aerial view of one such plant in operation at a location in india are shown below.

apart from the above against specific demands, particularly from overseas clients, akar makes containerized adbr plants. these are called aconset (akar containerized sewage effluent treatment) plants. numerous such plants are in operation in india, middle east countries, africa and in some neighboring countries also. a picture of one such plant is given below.

picture of the plant being sent to egypt is to be placed here.

about us

akar impex (p) limited formed in 1986, is a well known name in india and in many parts of the world in the field of waste water treatment and water treatment. this is why today akar has an enviable list of clients. presently akar’s exports contribute to about 40% of its total sales which speaks of its quality and capability. apart from its head office at noida near new delhi (india), it has three factories in the north india and offices all over india as well as overseas to serve customers better. the company is renowned as a solution provider and is reputed for its innovativeness, specialization, technical competence, reliable product performance and excellent service backup. this is the reason why numerous clients use akar’s products & services again and again. akar’s strength has been its in-house designing, manufacturing and assembling facility as well as ability to carry out turnkey execution of these projects. akar has competent technical, engineering, services and administrative teams to cater to their clients. the treatment systems designed and supplied by akar have been successfully operating in india and outside for the last several years. thus there is every reason why you should choose akar as your able partner when you are seeking any solution in the environment sector.