Company Information

Ask for more detail from the seller

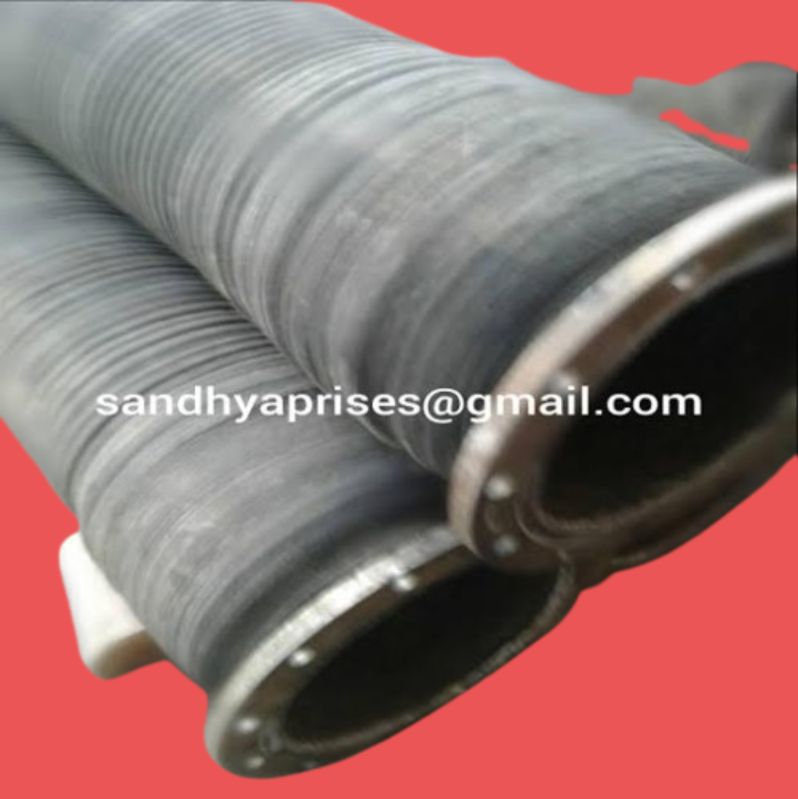

Contact Suppliersandhya enterprises manufacturer and supplier of air rubber hose for rmc plant. 3" id

lenght as per customer requirement.

fly ash hose

we have over 20 years of experience in this line of work and we are one of the few manufacturers across pan india who can manufacture a rubber hose having range from 25mm to 1000mm diameter.

manufacturer & exporter of fly ash hose our product range also comprises of expansion joint systems, elastomeric bridge bearings and architectural expansion joint

we have in store for our customers fly ash hoses, which are used in tank, truck, bulker loading/unloading or in-plant transfer of dry bulk cement, sand, lime, slurry, suction or discharge of abrasive materials,for more details pl contact to mr mithilesh chaudhary having 20 years experience in rubber and pvc products contact no 9652998932, email:sandhyaprises@gamil.com,website:www.sandhyaflex.com, payment 50% advance balance against proforma invoice. Delivery 7 to 15 days max.

An air rubber hose for RMC (Ready Mix Concrete) refers to a specialized hose used for the pneumatic transfer of air in the context of the RMC industry. RMC is a concrete mixture that is produced in a centralized batching plant and transported to construction sites in transit mixers.

The key characteristics of an air rubber hose for RMC include:

1. Construction: The hose is typically constructed with an inner lining made of synthetic rubber or thermoplastic material that is resistant to abrasion, impact, and degradation from compressed air.

2. Reinforcement: The inner lining is reinforced with high-strength synthetic fibers or steel wire braids to provide structural integrity and prevent the hose from bursting under pressure.

3. Flexibility: Air rubber hoses for RMC are designed to be flexible, allowing for easy maneuverability and installation in the construction site. This flexibility enables the hose to reach different points in the pneumatic system and accommodate movement during concrete placement.

4. Pressure resistance: The hose is engineered to withstand the specific working pressures involved in compressed air applications in RMC operations. It is designed to maintain its integrity and prevent leaks or bursts during operation.

5. Size and fittings: Air rubber hoses for RMC are available in various diameters and lengths to suit different application requirements. They can be fitted with standard couplings or connections for easy attachment to the air compressors, pneumatic systems, or other equipment.

It is important to ensure that the air rubber hose chosen for RMC applications is compatible with the specific compressed air requirements of the system, including pressure ratings and temperature limitations.

Regular inspection and maintenance of the air rubber hose are necessary to identify signs of wear, damage, or deterioration. Any worn or damaged hoses should be replaced promptly to prevent leaks or disruptions in the pneumatic system.

Consulting with reputable suppliers or manufacturers of air rubber hoses for RMC is recommended to ensure the selection of the appropriate hose that meets the specific requirements of compressed air transfer in RMC operations and complies with industry standards and regulations.