Listing ID #3816730

Company Information

Ask for more detail from the seller

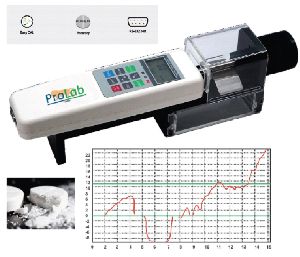

Contact SupplierThe UNIK Air Pressure Leak Tester is an equipment which will ensure that batteries with even minor leaks are detected. The equipment is a programmable micro processor based unit with various time settings that can be programmed through the keypads on the front of the controller. These timings are:

1. Fill Time during which the test pressure is filled in the component.

2. Settling Time during which the test pressure is stabilized evenly over the entire volume of the component.

3. Test Time during which the test component is subjected to leak test.

4. Exhaust Time used to exhaust the air from the test component.

The settings of test pressure and permissible leak can be easily programmed with the help of keypads.

The detailed test status and test results are displayed on 16 x 2 character alpha numeric LCD display providing record of the measured leak for each test along with other programmed parameters.

The operating procedure is very simple once the battery under test has been clamped and test started. Once the equipment is started, the pressure fill cycle starts. The set test pressure is filled in the battery. This cycle continues till the set air pressure is filled within the set fill time. After fill time is over the inlet of air into battery is stopped. At this point of time if the pressure is not filled upto the set pressure specified limits the controller gives a Gross leak signal. In case there is no gross leak; settling time starts with the pressure stabilizing evenly in the battery compartment under test. After the settling time is over the test time starts.

At the end of the set test time the reading is checked automatically and a comparison of pressure with preset value is done. If there is a drop in pressure during the test time and if this drop is greater than maximum permitted leak the fault indicator glows. In case the leakage is within acceptable specified limits the OK signal glows.

An audio visual alarm helps in segregation of acceptable and rejected batteries thereby eliminating any possible error due to the operator’s subjective judgment.