Listing ID #3903059

Company Information

Ask for more detail from the seller

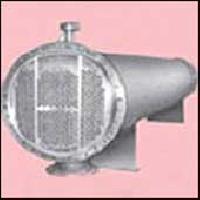

Contact SupplierAir Preheaters (APH) is the Shell and tube type Heat Exchangers used for preheating the air which is fed to the boiler or furnaces/kilns for combustion of fuels. Its primary objective is to extract the waste heat from the flue gases leaving the boiler.

Thermodyne Engineering Systems manufacture Air Preheaters and are given as a standard side accessory along with the main equipment – Boiler, in a Packaged Type Boiler, Combi Boilers.

Why is hot air sent to the furnace?

For generating fire in a boiler furnace 3 main ingredients are needed: Fuel, Air and Ignition. Air is used in a Boiler for combustion of fuel. Based on the stoichiometry calculation, right quantity of air along with excess air is fed into the boiler furnace for the combustion of fuel. Generally, fuel fed to the boiler is at normal room temperature and for combustion of fuel to take place; the temperature of the fuel is increased from its room temperature to ignition temperature. So to increase the efficiency of combustion process as well as a boiler, hot air is fed to the furnace for the combustion of fuel.

Type of Air Preheaters (APH)We manufacture different type of air preheaters:-

Air Preheaters have a shell and tube type construction where exhaust heat from the flue gases is transferred to the air when they come in indirect contact with each other.

Air Preheaters consist of a shell where tubes are arranged in a square or triangular pitch and are welded to a tube plate. Depending upon the type of operation and ease of cleaning, flue gases and air can be allowed to travel either shell side or tube side interchangeably.

Thermodyne Boilers finned tube air preheaters are designed to maximize the efficiency by increasing the heating surface area without increasing the space requirement.

Thermodyne Engineering Systems manufacture air pre-heaters that are tailor-made to suit the customer’s requirement. Our Air Preheaters are designed in both 1 and 2 pass for both flue gases and air to extract maximum heat from the flue gases.

We manufacture air pre-heaters for wide capacity range and can satisfy the various fuel requirements of a customer such as: