Listing ID #5385181

Company Information

Ask for more detail from the seller

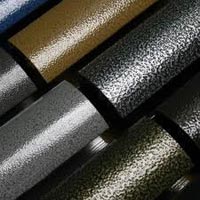

Contact SupplierMoS2 and solid lubricants based air-drying anti friction coating

Benefits

\n

Applications

\n

Directions for Use

Shake the can vigorously for a couple of minutes before spraying till the bearing noise from inside the container is audible. Repeat before every application. Spray onto a clean, dry and degreased surface. Only a thin film of this lubricant is required. Allow solvents to evaporate. Spray from a distance of 20-30 cms. Repeat if necessary. Excess lubricant may fall off during assembly. For cleaning the valve dip-tube after spraying, invert the can and depress the actuator button for a few short bursts till only the clear propellant comes out.

Caution:- Contains flammable solvents and propellant. Do not spray near naked flame, hot surfaces or energized equipment. Use with adequate ventilation.