Listing ID #4168356

Company Information

Ask for more detail from the seller

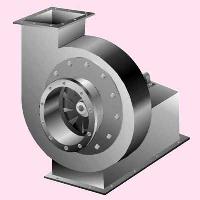

Contact SupplierThis turbine blower is a non- postive displacment , high volume , pressure , blower that can operate as either a compressor or a vaccum pump. It is also known as other names such as regenerative blower , vortex blower and side channel blower . All of names describe the basic principle of operation of the blower.

The blower consist of an impeller mounted diectly on a motor shaft and is rotated at a high speed of about 2900 R.P.M. On the periphery of the impeller are a large number of radial blades. The impeller is positioned between 2 end plates with the blades located with a chnnel on either side.

The turbine blower is , ineffective , a multi stage compressor with each regeneration of the air becoming another " stage".

The basic construction of a turbine blower means that the only moving part is the impeller . Nothing touches except bearings. The method of compression means that there is no requirement for lubrication in the compression chamber. The discharge air is Oil- less. No oil aerosols are present in the discharge air, nor carbon dust generted by sliding wanes. The blower should be mounted vertically or horizontally.

APPLICATION

Air pollution monitoring equpiment, hopper loader, vaccum lifting, gas transfering, electroplating plant, effluent treatment plant , waste water treatment plant , manufacturing of textiles, medical laboratory and measuring equpiment, printing and paper handling , vaccum packaging, reprographic industry, aeration of fluids, pneumatic coveying, plastic industry, industrial ovens, vaccu cleaners.

| MOTOR | CAPACITY (CFM) | PRESSURE (PSI) | VACCUM ( M BAR) | WEIGHT | INLET/ OUTLET( D INCH) |

| 0.50 HP | 53 | 1.26 | 85 | 22 | 1.25 |

| 0.75 HP | 71 | 1.75 | 120 | 25 | 1.25 |

| 1 HP | 118 | 1.96 | 130 | 27 | 1.5 |

| 1.5 HP | 147 | 2.17 | 145 | 36 | 2 |

| 2 .0 HP | 177 | 2.8 | 165 | 40 | 2 |

| 3 .0 HP | 235 | 3.15 | 220 | 49 | 2.5 |

| 5 .0 HP | 412 | 3.5 | 245 | 83 | 3 |

| 7 .5 HP | 529 | 3.78 | 260 | 100 | 3.5 |

| 10 HP | 706 | 4.9 | 340 | 130 | 4 |