Listing ID #4067209

Company Information

Ask for more detail from the seller

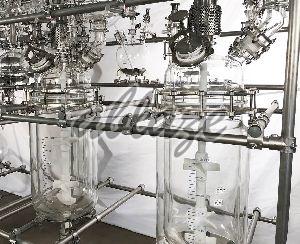

Contact SupplierWe offer various types of mixing agitator for Stainless, Inconel, Hastalloy Reactors. We can design and offer best-suited agitator based on your input. We also offer commissioning of the system at clients works.

we offer the system with

Stuffing box, Mechanical seal as well as Magnetic drive

We supply a wide range of mixing systems to the Pharmaceutical, Specialty Chemicals, Biotech, Paints Dyes and intermediates plants as well as Polyester plant industries.

We design and manufacture mixing systems for various applications:

Advantages

The agitators offered by us are guaranteed for the stated mixing performance. If the specified performance is not achieved the agitator will be modified or replaced at our cost.