Listing ID #3961897

Company Information

Ask for more detail from the seller

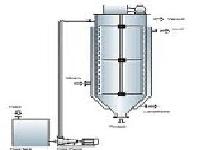

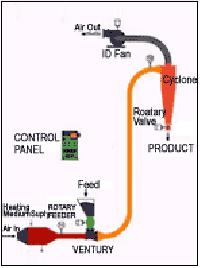

Contact SupplierDue to its inherent design features, it is ideal for thermal treatment of solutions and heat sensitive products, where reduced operating temperatures and vacuum operating pressures are desirable. The typical Agitated Thin Film Evaporator consists of a tubular heat transfer area with an external heating jacket and a fast-revolving, inner rotor with flexible or rigid wiper elements. The driving speed is adapted to the product being handled, its particular specifications and task.

The feed product is evenly distributed by the rotor and its wipers over the heating surface, forming a thin liquid film of uniform thickness. Highly turbulent swirls are produced at the tip of the rotor blades and wipers with intensive mixing and agitation of the product, as it comes into contact with the heating surface. This assures excellent heat transfer combined with constant renewal of the product film and provides an even heating and short residence time of the product through the heated zone.

Key Advantages

Applications

Mainly used for difficult vaporization and heat exchange processes, especially where products to be handled are highly viscous and conventional plants can no longer meet user demands because heat transfer is insufficient. Due to the liquid film, mechanically generated on the heating surfaces, thin film equipment achieve much better heat transfer rates, even with highly viscous products containing solids.