-

Supply Type

Exporter

-

Preferred Buyer Location

All over the world

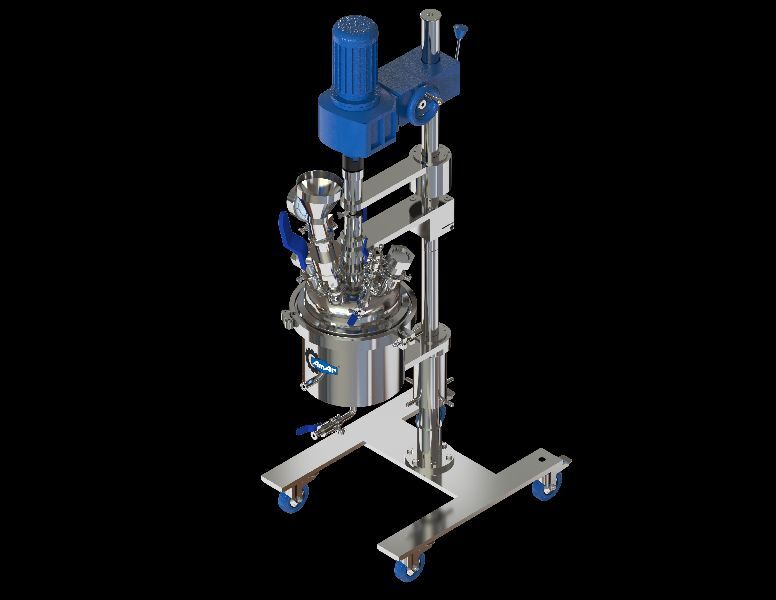

Volume: 1 ltrs to 100 ltrs slurry volume

Filtration Area: 0.005m² to 0.5m²

Removable filter basket, size from 5μm to 20μm

Design pressure: -1 to 4 bar

Design Temperature: -20°C to....

View More Details