Listing ID #3795922

Company Information

Ask for more detail from the seller

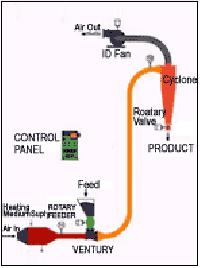

Contact SupplierThis is a combination of filter and dryer unit in single equipment to achieve economy in process, space and energy thereby improving profitability. This equipment can be used in manufacturing process of various Pharmaceuticals, Intermediate Compounds, Chemicals, Fine Chemicals, Agro Chemicals, Insecticides, Pesticides, Dyes and Food Products.

The Agitated Nutsche Filter Dryer is a closed vessel designed to separate solid and liquid by filtration under pressure or vacuum. The advanced technology of agitation and hydraulics used in the equipment makes it versatile and user friendly. The resulting wet cake can be reslurried and washed thoroughly with water or solvents unlike in untsch filters or centrifuges. Wash liquid quantity can be controlled and recycled, reducing effluent load. The discharge of wet cake is automatic. If the process demands filtration in chilled or hot condition, it is also possible. Drying of wet cake is also possible when drying features are incorporated. The unit consists of a totally enclosed and sealed cylindrical shell fitted with a agitator assembly which moves horizontally as well as vertically. The cylinder operates under pressure or vacuum or both. The closed operation ensures odorless, contamination free and nonpolluting working conditions maintaining product purity and hygiene. The equipment is functionally safe and easy to operate.

The equipment is functionally safe and easy to operate. It can carry out various phase of process operations, viz: Crystallization, filtration, extraction, Discoloration, Washing and drying. The number of conventional machines employed for filtration process are also reduced. It has multi- functional utility, saves on power, labor, floor space, material wastage and time.

Additionally, the equipment is fitted with a stirrer mechanism which efficiently agitates the slurry during cake washing, smoothes and squeezes the cake during filtration and assists in the automatic discharge of the cake. A side discharge arrangement is provided, closing and opening through hydraulic / mechanical means. A filter plate with filter cloth is fitted at the bottom of the shell for separating liquids from solids. The cake is retained on top of the plate. The upward and downward movement of the agitator assembly is utilized for cake washing, compressing, drying and discharge of the cake. A vacuum pump connected to receiver is installed for discharging of liquids and vapor collection. The cylindrical shell can also be provided with a jacket. A filter plate is located at the base of the vessel in level with the discharge port. The filter medium, usually a filter cloth, is fitted on the filter plate which is replaceable type.

In addition a special multilayered filter plate can also be provided instead of filter cloth. In dryer construction heating is provided on shell by limpet in bottom by jacket and through hollow agitator and blades. Vacuum is applied for fast drying.

It has multi- functional utility, saves on power, labor, floor space, material wastage and time. We use sophisticated technology that combines hydraulics and agitation, which makes the Agitated filter dryer easy to use and very versatile.

| SALIENT FEATURES : | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| MODEL | RV-ANFD-50 | RV-ANFD-100 | RV-ANFD-200 | RV-ANFD-300 | RV-ANFD-500 | RV-ANFD-1000 | RV-ANFD-1500 | RV-ANFD-2000 | RV-ANFD-3000 | RV-ANFD-5000 |

| WORKING VOLUME | 50 | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 5000 |

| CAKE VOLUME | 25 | 50 | 100 | 150 | 200 | 400 | 750 | 1000 | 1500 | 2500 |

| FILTER AREA | 0.2 | 0.4 | 0.5 | 0.6 | 0.75 | 1.1 | 1.5 | 2 | 3 | 5 |

| VESSEL DIA | 425 | 600 | 700 | 800 | 1000 | 1200 | 1400 | 1600 | 2000 | 2500 |

| VESSEL HT | 400 | 400 | 550 | 600 | 600 | 900 | 1000 | 1000 | 1000 | 1000 |

| BOTTOM OPENING STROKE | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| DISCHARGE VALVE ID | 150 | 150 | 200 | 200 | 250 | 300 | 300 | 400 | 450 | 450 |

| AGITATOR RPM | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| AGITATOR DRIVE | 1 | 1 | 2 | 3 | 5 | 7.5 | 10 | 12.5 | 15 | 20 |

| AGITATOR VERTICAL STROKE | 200 | 200 | 200 | 200 | 250 | 250 | 300 | 400 | 450 | 450 |

| AGITATOR UP DOWN SPEED | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

| OVERALL DIMENSION | 1300 X 1300 X 2400 | 1500 X 1500 X 2500 | 1700 X 1700 X 3000 | 1800 X 1800 X 3000 | 2000 X 2000 X 3300 | 2200 X 2500 X 3675 | 2300 X 2300 X 3800 | 2500 X 2500 X 3800 | 2800 X 2800 X 4375 | 3500 X 3500 X 4600 |

| DESIGN PRESSURE | VESSEL – FULL VACUUM, JACKET / LIMPET – 4 BAR | |||||||||

| DESIGN TEMP | 150 DEGREE | |||||||||

| FINISH | INTERNAL : 240GR. MIRROR FINISH , EXTERNAL : 180GR. MATT FINISH | |||||||||