Listing ID #3869189

Company Information

Ask for more detail from the seller

Contact SupplierPurpose of Inter-cooler and after cooler Heat exchangers

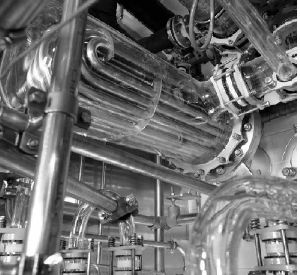

Target equipment Inter-cooler and after cooler Heat exchangers are utilized in several industries, especially in chemical plants and oil refineries, textile industries. The purpose of these heat exchangers is to transfer heat from machinery to the other, most often from a liquid to the other. The constant efficiency of the heat exchanger demands for regular inspection to assess the equipment integrity An inter cooler, also known as the charge air cooler is heat exchange device of the air to air or air to liquid kind that is used on supercharged and turbocharged internal combustion engines in order to maximize its volumetric efficiency by raising the charge density of intake air via almost isobaric.

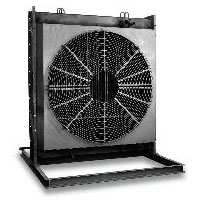

Types of inter cooler/ after coolerThe inter-coolers, sometimes called as the after coolers, come in varied shape, design and size based on the special requirements and performance of the supercharger system . Some of the usual spatial designs are

Each of these kinds could be cooled with an air to liquid system, air to air system , or its combination.

Function of inter cooler/ after coolerOur inter-cooler heat exchanger to successfully cool the air passing through the device, The inter-cooler needs to be cooled with the aid of some outside means.

Many of the inter-coolers undergo cooling like an engine radiator where the air flows above the inter-cooler fins outside, that in return cools the air present inside the inter-cooler. Thus it is known as air to air inter-coolers. Some of the inter-coolers that are water cooled rather than by air are known as air to water inter-coolers or after coolers.

Advantages of inter cooler/ after cooler