Listing ID #6350802

Company Information

Ask for more detail from the seller

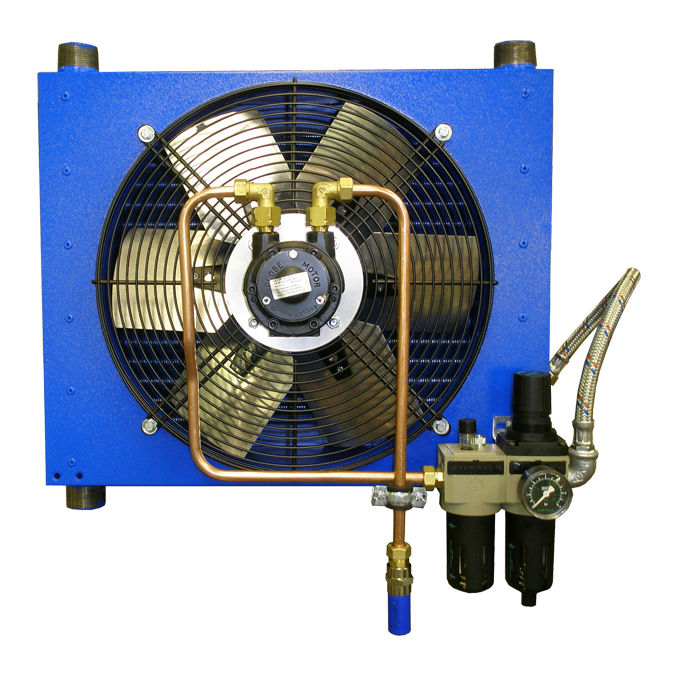

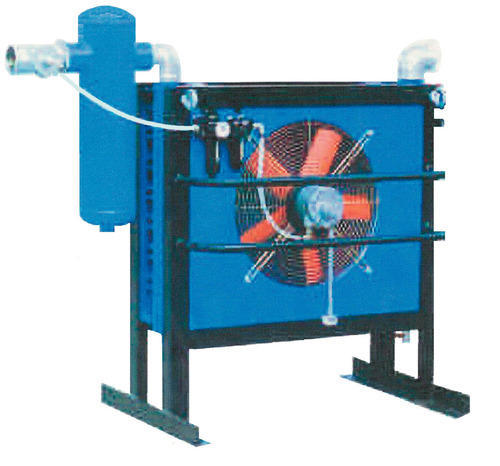

Contact SupplierAfter cooler:

Water or moisture is not desirable in the transmission lines of an air compression system. Water carried through the lines washes away lubricating oil from the tools the compressed air is running. This causes the tools to operate sluggishly & increases the need for maintenance. The effect is compounded in high speed tools, where wearing surfaces are limited in size & excessive wear reduces efficiency by creating air leakage.

Further problem results from the decrease of temperature caused by sudden expansion of air at the end. This low temperature creates condensation, which freezes around port and valves & impairs efficiency. These conditions can be minimized by removing the moisture from the air directly after compression, before the air enters the distribution system.

The compressed air discharged from compressor is hot. Compressed air at these temperatures contains large quantities of water in vapor form. As the compressed air cools this water vapor condenses into a liquid form. As an example if an after cooler is not used, a 200 scfm compressor operating at 100 psig introduces 45 gallons of water into the compressed air system each day.

Functions of compressed air after coolers

Cool air discharged from air compressors via the heat exchanger

Reduce risk of fire (Hot compressed air pipes can be a source of ignition)

Reduce compressed air moisture level

Increase system capacity

Protect downstream equipment from excessive heat

Established in the year 2019, we at Fitzer Incorporation are one of the most renowned and reputed manufacturers, suppliers, and exporters of industrial equipment. We proficiently deal in Heat Exchangers, Heating Process Equipment, Cooling Process Equipment, Desiccant Dehumidifier, IQF Tunnel Freezer, Cold Storage Room, Convection Recuperator, Pressure Vessels, Storage Tanks, and Thermal Energy Storage systems. All of our products are manufactured and designed as per the global standard such as API, ASME, IBR, TEMA, and ASHRAE.

We have established world-class transportation equipped with advanced and newest technology machines that assists us in organizing the products with dimensionally accurate, extremely efficient, highly durable, corrosion-resistant, and strong construction. Moreover, with the highly demanded items, we give properly planned fabrication-erection services for industrial plants by offering system designs, fixing, and after-sales services.

We have appointed a team of professionals and well-trained experts who are aimed to create machines to manufacture products from the best quality raw materials following the best industry terms and norms.

Our team of quality controllers performs a series of tests to inspect the overall quality and operations of the products.

Fitzer Incorporation is working under the able motivation and guidance of Mr. Siddhi Chavan. Since our beginning, we have followed the policy of blending price and quality for offering the best possible items to valuable customers. We aim to increase our business shortly while keeping up our striking track record.