Listing ID #4615558

Company Information

Ask for more detail from the seller

Contact SupplierRotary machine consisted of- Container Feeding Turn Table Indeed Conveyor

Rotary Turret with-

1.Automatic 2 Head Rotary Liquid Filling Unit

2.Single Head Crimping

3.Automatic 2 Head Gas Charging Unit

SPEED- Upto 30 Containers Per Min.

Technical Parameters-

Pump Loading-Manual

LPG Columns & Storage tank for Aerosol Containers

Consisted of 6” dia. Column MS seamless pipe with pressure gauge & filtering unit & then after pass the filter 500Lit capacity of MS Storage tank to pass the filtered Gas.

All Contact Parts-SS316

FLP Arrangement

Filling capacity-10ml to 200ml

Consisted of NO Container NO Liquid Filling & NO Container - NO Pump Loading (Pump loading by manually) as well as No Container No Crimping & No Container No Gas Charging

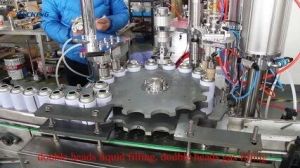

Consisted of Simple System for UHMW/CAST NYLON TURRET with Height Adjustment Any Change over for Varies as per dia. of the Containers in Crimping & Gas Charging unit.

Gassing Head for Charging the LPG Gas which is applying with Booster Pump (Individually operation) & it’s operated with Two Stations ie. Initially filled with 40% & then after remaining 60% filled.

Indexing with Pneumatic operation MANIFOLD separately for Rotary Liquid Filling as well as Crimping & Gas Charging Stations.

Crimping Device-Pneumatic Operated

Gassing Device-Pneumatic Operated

Turn table Motor & Conveyor Motor with FLP (from Rotary Liquid Filling M/C to Gas Charging M/C) 0.5HP & 1HP respectively with Make - HINDUSTAN & with Suitable Gear Box Ratio Make - Bonfigloli as per requirement of Drive arrangement.

LPG gas columns (will be kept at outside of the m/c) for molecules filtration before gas passing to the Gas charging stations via providing the storage tank.

Machine Dimensions: (Length 5000mm x Width 2500mm x Height 2500mm Max.)

Machine Weight Approx: @ 850 Kg max.

Total Power Consumption 1KW Max 3Ph. 440V AC 50Hz for All FLP Motors

Total Air Consumption requires Dry Compressed Air up to 12 Kg/Sq. cm OR up to 16 CFM.

Operational Description-

The Empty Containers Feed Manually onto the Feeding Turn Table which moves forward slowly up to the Filling Heads. It’s detect with FLP Sensors & after getting the feedback through the panel. Filling Nozzles will come down & filled the Containers as per settled Volume. This all operation will be done with Pneumatically operated.

This Filled Containers moves forward & comes on to the further Line of Crimping & Gas Charging M/C Conveyor. During that time Pump Loading will be manually into the Filled Containers. It’s Moves forward to the Turret Cavity as per size of the Containers. This containers Index & rotate Clock wise with proper guiding & after indexing completion; Crimp the Pump with Pneumatic operated Cylinders. Crimping Setting will be done as per trial & error method which will set once a time with using Crimping & Checking the Depth Gauge as per standardise.

After Crimping the pump; again Index the Turret with Crimped Bottle & Comes at Gas Charging station. At that time sense the container & give the signal to the Gassing Head. Gas will be fill into the Container which is pass through the Booster Pump ie. For Pressurize Gas filled into the Containers. For these operation we will provided Two separate Booster Pump due to easily filled the container with High Volume & for better accuracy as well as increase the productivity. These filled container moves forward to the next station & comes out at the Exit side conveyor. This whole assly. will be provided with Height Adjustable type due to Various Container sizes. Gas Charging will be operate as per requirement of Gas has to be charge & filled into the Containers ie. Either 2Nos OR 3Nos (As applicable) Gas charging will be applied as per depends upon the Filled quantity.

These Gas Filled containers are moves forward from Gassing Exit Conveyor. This finish container comes out at the exit side of the Conveyor.

This whole entire cycle repeat again & again with all sequence one by one & with Pneumatically as well as Electrically Logic operation (wherever applicable).