Listing ID #4274957

Company Information

Ask for more detail from the seller

Contact Supplier» product details: -

frame:

it is fabricated with prime m. s. plats. its interlocked construction where the bed is directly supported on the side walls, ensures consistent accuracy and perfect alignment. due to its generous proportions, it imparts ample strength to the complete assembly and ensures against deflection even while working at full rated capacity.

ram and bed:

made from steel plates of suitable thickness, machined for straightness and parallelism of the working surfaces. ram is guided and supported throughout the stroke by accurately machine guide ways.

drive system:

power a transmitted to the ram through two individual gear drives for uniform load distribution throughout the length. this also reduces the torsional stresses on the eccentric shaft. electric motor used is of sufficient h p. which reduces slowdown of flywheel and increases energy available per stroke. the gear and pinion are made out of carbon-alloy steel.

ram adjustment:

motorized ram adjustment is provided to facilitate quick and accurate adjustment of required bending angle. a spring-loaded dog clutch enables to angular setting of ram.

clutch and brake:

clutch: press brakes are provided with high torque low-inertia friction clutch.

brake: heavy duty mechanical brake ensuring immediate breaking of ram on releasing the pedal. clutch operating levers are designed in such a way that minimum engaging force is required at the pedal.

front and rear gauge:

front gauge: t slotted front guage fabricated from milled steel detachable.

rear gauge:

hand operated screw type rear gauge is provided to facilitate repetitive jobs.

lubrication:

all bearing parts and guide surfaces are lubricated through connected oil cups and hand operated lubrication pump.

standard equipments:

standard v-block (die) and punch. front & rear gauge. motor pully, foot pedal, gear & fly wheel guards and standard instruction manual.

standard accessories:

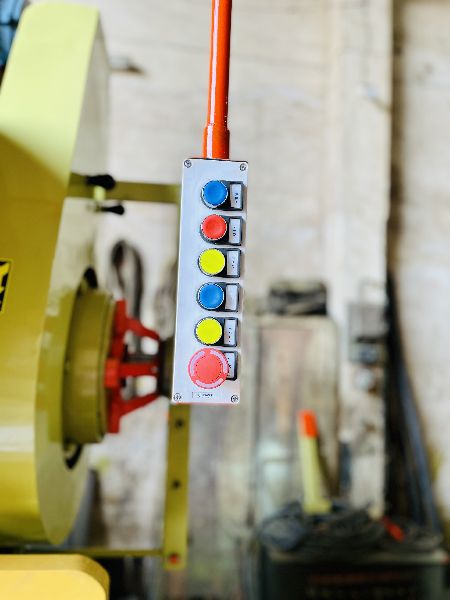

electric motor control panel board, vee belts, push button pendent, stroke counter, manual lubrication pump, electric and lubricating pipe, fittings and wiring.

optional accessories:

goose neck punch and other tooling (drowing as per required)

power supply:

400/440 volts, 3 phase, 50 cycles.

note: electrical items & blade are not under warranty.

Specification

| Model | Tone | Bending Capacity in Mild steel Length - X Thickness D | Clearance between Housings | Stroke Per Minute | Stroke of RAM (M.M.) | RAM Adjus- tment (M.M.) |

Shut Height RAM Strock Down | Depth of Throat (M.M.) T |

Main Motor HP / KW |

RAM Adjus- tment Motor HP / KW |

Overall Dimension in M.M.

|

|||||

| PPB-1 | 20 | 1525 x 1.6 | 1000 | 25 | 50 | 40 | 175 | 200 | 3 / 2.2 | 0.5 / .37 | 1900 | 1050 | 2200 | |||

| PPB-2 | 25 | 2000 x 1.6 | 1220 | 25 | 50 | 40 | 200 | 250 | 5 / 3.7 | 0.5 / .37 | 2250 | 1150 | 2400 | |||

| PPB-3 | 40 | 2500 x 2 | 1535 | 25 | 50 | 40 | 200 | 250 | 7.5 / 5.6 | 1 / .75 | 2750 | 1400 | 2600 | |||

| PPB-4 | 65 | 3125 x 2.5 | 1900 | 25 | 75 | 50 | 250 | 300 | 10 / 7.6 | 1.5 / 1.1 | 3400 | 1575 | 2675 | |||

| PPB-5 | 65 | 2000 x 4 | 1370 | 25 | 75 | 75 | 275 | 300 | 10 / 7.6 | 1.5 / 1.1 | 2400 | 1575 | 2675 | |||

| PPB-6 | 80 | 2500 x 4 | 1535 | 25 | 75 | 75 | 275 | 300 | 12.5 / 9.7 | 2 / 1.5 | 2800 | 1600 | 2950 | |||

| PPB-7 | 100 | 3125 x 4 | 1900 | 25 | 75 | 75 | 275 | 300 | 15 / 11.2 | 2 / 1.5 | 3400 | 1800 | 3400 | |||

| PPB-8 | 120 | 2500 x 6 | 1700 | 25 | 75 | 75 | 275 | 300 | 20 / 15 | 2 / 1.5 | 2900 | 1800 | 3400 | |||

| PPB-9 | 150 | 2500 x 8 | 1700 | 25 | 75 | 75 | 275 | 300 | 25 / 18.7 | 2 / 1.5 | 2900 | 1800 | 3400 | |||

| PPB-10 | 150 | 3125 x 6 | 1900 | 25 | 75 | 75 | 275 | 300 | 25 / 18.7 | 2 / 1.5 | 3400 | 1800 | 3400 | |||