Listing ID #5097139

Company Information

Ask for more detail from the seller

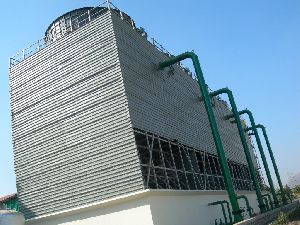

Contact SupplierICTMCo. offers field erected Pultruded FRP cooling towers. These cooling towers are designed using Pultruded FRP sections, FRP sheets for cladding, Stainless steel for fasteners and other hardwares. Properties of Pultruded FRP gives the cooling tower distinct advantages over other material of construction like concrete or timber. Engineering at ICTM CO. gives shape to the finest of cooling towers whose aesthetic beauty make cooling tower area very special place in the plant. The strength of Pultruded FRP can be compared with that of steel. With FRP the question does not stop at performance but carries on to beauty and aesthetics. With wide range of colours to choose from, the colour of cooling tower can be matched to rest of the plant. No wonder when ever a timber cooling tower reaches its end of its life, there is always a demand to convert it to Pultruded FRP cooling tower.

For large field erected cooling tower Pultruded FRP structural members are used for constructing the cooling tower. Pultrusion is an industrial process that is dedicated to continuously process Reinforced Plastic having constant cross sectional shape like I, C, U, H, flat panels etc. Reinforcing fibers are pulled through a Plastic liquid impregnation bath through rollers etc. and then through a shaping die followed with a curing action. It produces products which meets high structural requirements, high weight to strength performances, electric requirements etc. In case of Pultruded FRP Cooling Towers materials are shipped to the site and cooling tower is erected first by putting up the structural framework and then fan deck, torque tube, mechanical assembly, fills, casing sheets etc.

Pultruded FRP based cooling towers have structures having proven Braced Frame Design. These structures are connected to the ground with steel angles and base plates anchored and grouted to the basin. Hardware used at all the places are stainless steel. No piers and pilasters are used in the structure. Frame, Casing, Fan deck, Fan cylinder, staircase, railing, light poles, ladders etc are all of FRP. Wherever necessary anti skid surfacing is used for safety of Operation and Maintenance personnels.