Listing ID #4827238

Company Information

Ask for more detail from the seller

Contact SupplierApplication :

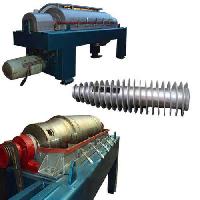

The Decanters / Solid Bowl Centrifuges are used for clarification (liquid / solid separations), dewatering and classification duties in various process industries.

Typical Products Processed :

Design Features :

Operations :

Rotofilt Engineers Limited is a name that is counted amidst the eminent firms that are providing a wide range of centrifuge, pressure filter, and much more. We are a noteworthy manufacturer, exporter, and supplier of automatic vertical pressure filter, and industrial centrifuges such as basket centrifuge, decanter centrifuge, peeler centrifuge, and pusher centrifuge. We are a brand leader in the industry of solid liquid separation technologies. We have been able to achieve the 3rd position in the market for our supply of automatic vertical pressure filter and other products. We are completely focused on the improvement of the solid liquid separation technology. We keep our focus on the customized development of the product, aftermarket solutions, and application engineering.

Rotofilt Engineers Limited, deeply rooted in Ahmedabad (Gujarat, India), is one of the renowned fraternities that are involved in manufacturing, exporting, and supplying the finest quality centrifuge and other products. The company has been operational in the industry since the year 1996. In the beginning, we produced only pusher centrifuges and gradually expanded our business to different other products like decanters, vertical baskets, etc.

Our Engineers

We have a team of efficient engineers, who develop the Rotofilt products while making it energy efficient and cost effective. We aspire to give hassle free performance of our products to our revered patrons.

Our Vision and Mission

Vision: To be leading solid/liquid solution provider in global arena by providing exceptional value and updated technology to the customers and creating overall goodwill amongst the people involved.

Mission: To consolidate ROTOFILT as leading solution provider of solid /liquid separation to process industries by providing our customers high efficient, cost effective equipment which enables qualitative higher returns consistently.