Company Information

Ask for more detail from the seller

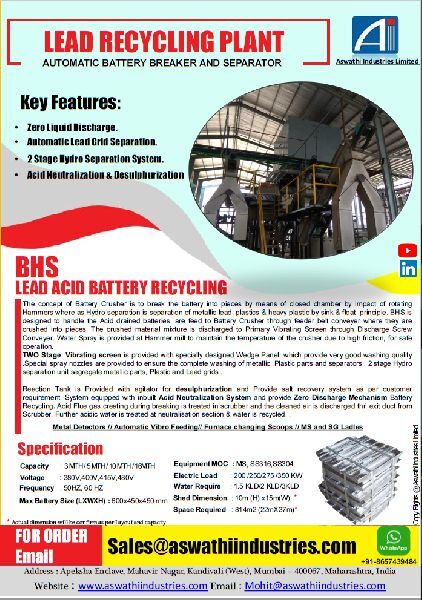

Contact Supplieraswathi industries limited offers complete solution and machinery for lead recycling and alumium recycling equipment.

the smelting unit is designed to recover the lead by processing lead-bearing material from spent lead-acid batteries. to recover the lead from lead-bearing materials, it is necessary to carry out the chemical reactions at rotary furnace in presence of reagents at high temperatures to remove the oxygen and sulphur elements from lead oxide and sulfate from lead-bearing material. this is basically a reduction process. wood charcoal or petroleum coke (coal) is the most commonly used reducing agents in the lead recycling industry. due to chemical reactions at the furnace, slag is formed which is having a high melting point and viscous in fluidity. in order to make its melting point lower and have good fluidity, fluxing agent soda ash/sodium carbonate with iron chips is added in a specified quantity.