Company Information

Ask for more detail from the seller

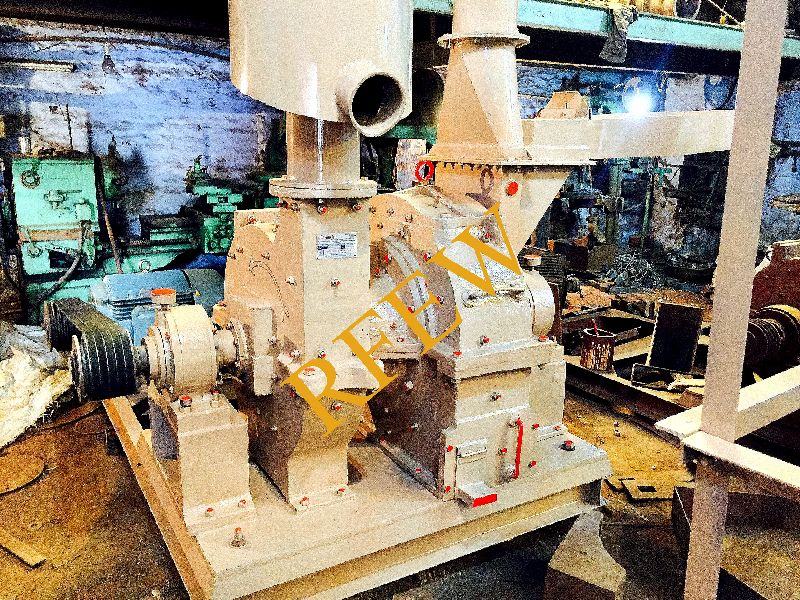

Contact Supplieris a high swing type grinding mill pulverisation & is achieved by the grinding chamber. The fine powder is swept by the blower suction from the grinding chamber via whizzer cone. The function of the whizzer cone is to check the oversize particle and thus to regulate fineness sand is separated out from the material from the grinding chamber.

the blower delivers the pulverised powder in the cyclone air separator. The powder is discharged from the cyclone spout, the seperated air return to the grinding chamber to complete the air circle.

the pulverizer is manufactured from best raw materials. The main body of the grinding chamber, cone body/ whizzer chamber and the blower are made up of alloy steel casting heavy body which comes in contact with the material is lined with changable manganese steel lining scissor plates 8 pieces set. The striking face of the grinding

main body construction -

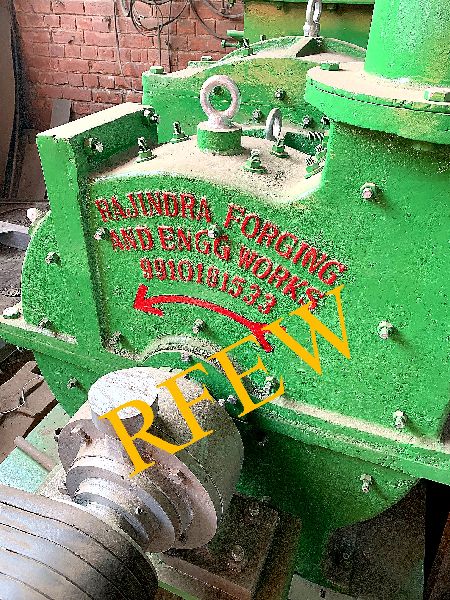

rajindra impact pulverizer details -:

first time in india alloy steel casting complete pulverizer body - 36” body size without liner 32” body from within with liner so grinding chamber leaves exact more space, thus increasing grinding space and resulting in more production.

benefits of alloy steel casting pulverizer body -: alloy steel casting complete pulverizer body is done by pattern work which is heavier than other fabricated or cast iron bodies of pulverizer, this body line never get damaged or have any erosion on it in time and thus increasing its life for a very long time, its well jacaketed by manganese steel linner as preference of the buyer, and linning which protects the body line

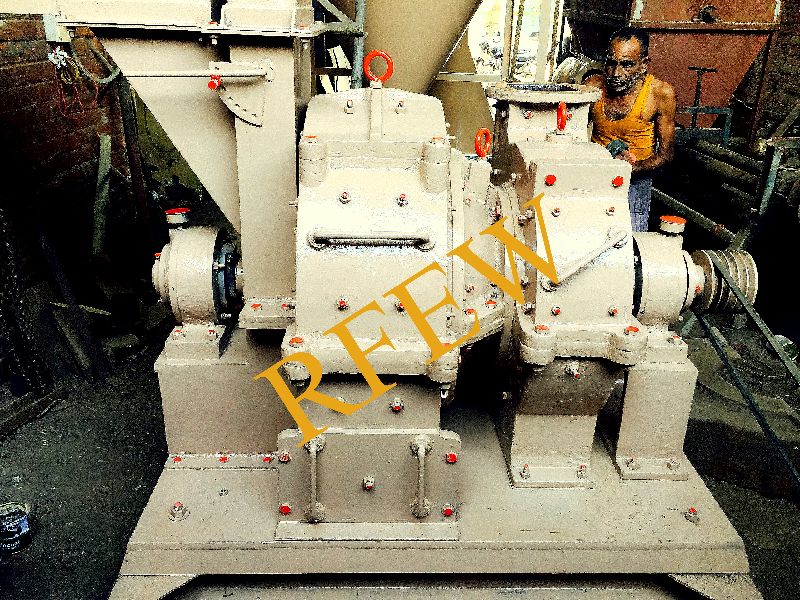

manganese steel liner – all pulverizer inner liner and lining are in manganese steel casting which has better results and less erosion than fabricated or cast iron.

pulverizer blower body – extra side lining/ liner – resulting in protection of the blower body from wear and tear and giving long life. Blower upper and lower body. Complete blower body side thickness with lining , upper blower body with lining with blower fan heavy structure fabricated with our new design concepts which does not the dust behind.

pulverizer grinding chamber body with router plate and with fitted router lining and forged alloy steel forged hammer – 4 pcs. With 7 pcs. Manganese steel casting liner set - scissor type side lining chamber body plates .

pulverizer shaft - heavy duty railway axle shaft – aligned with heavy duty casting bracketssupporting the bearing , with aligned spherical bearing with side cover and coupling, the shaft from outside the body line is fitted with cover namda which does not allow any dust leakages while running of the machines and refilled grease cup which reduces keeping less than .1% dust intake and increasing bearing life.