Listing ID #1286501

Company Information

Ask for more detail from the seller

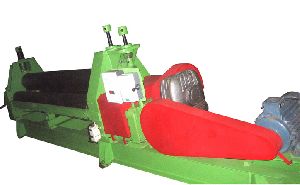

Contact SupplierWe are one of the renowned Manufacturers and Suppliers of a wide array of 3 Roll Plate Bending Machines. The 3 Roll Plate Bending Machine has infinitely variable speed of rolling as per requirement. These 3 Roll Plate Bending Machines have faster rolling for smaller thickness. We provide these 3 Roll Plate Bending Machines at rock-bottom prices. The 3 Roll Plate Bending Machines are operated easily and are highly durable.

Width : 2000mm, 2500mm, 3100mm, 3600mm & 4100 mm.

Capacity in Thickness : 12, 16, 20, 25 & 30 mm.

Standard Features : Hardened rolls up to 60 R. C. Cone guide adjustable on button section rolling arrangement digital display for pressure arm A & B.

Optional Features

Unique Features