Listing ID #1392653

Company Information

Ask for more detail from the seller

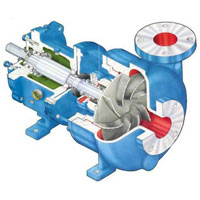

Contact SupplierWe design high performing centrifugal process pumps that are reckoned for speed and efficiency. Centrifugal process pumps, offered by us, are manufactured from optimum quality raw materials using advanced technology that ensures their maximum output with minimum maintenance.

Available in

Material of Construction

Conforms to

Applications

|

|

Product Features