Company Information

Ask for more detail from the seller

Contact SupplierBeing a client-centric company, we are committed to offering superior quality Powder Coating Booth to our clients. Our dexterous professional have made the entire range of this Coating Booth using premium quality raw material in compliance with the international quality standards and norms. These booths are proficient of providing a qualitative coating of various powders effectively. All across the world, it is highly applauded for its high performance, effectiveness, easy installation and longer service life. It is available to our clients at an affordable range of price.

Details : The powder coating booths are not simple spray chamber of sheet metal with some recovery, but they are the output of engineering and dedicated R&D staff working round the clock. Each and every equipment designed & manufactured by us is fruit of continual improvement going at our R&D. Why our powder recovery booth: The carbon steel powder coated spray chamber with the multi-cyclone recovery gives almost 100 % powder utilization. It is maintenance free and has a very long life. The powder booth is easy to clean, resulting in a quick color change and is safe to operate. No powder spillage out of the booth and maximum recovery through the multi-cyclone results in pollution control. Improved Transfer efficiency. Pollution free operation. Safety measures. Maximum recovery efficiency. Durability. Quick colour change. Velocity of booth should be: Appropriate enough so that maximum powder should be attracted on the article. If suction velocity is more, more amount of powder will be sucked towards cyclone & less on article. If suction velocity is less, then powder will come out from cutout & surroundings will be polluted. Selection Criteria: Easiness in colour change , No. of colour change ,Frequency of colour change. Selection of Booth design. Size of Article ,Weight of Article. Selection & type of Track / Trolleys from 1 side or 2 sides. System of track / trolleys. Any other type of material handling.

Recovery Booth

The carbon steel powder coated spray chamber with the multi-cyclone recovery gives almost 100 % powder utilization. It is maintenance free and has a very long life. The powder booth is easy to clean, resulting in a quick colour change and is safe to operate. No powder spillage out of the booth and maximum recovery through the multi-cyclone results in pollution control.

Powder coating booth : The powder coating booths are not simple spray chamber of sheet metal with some recovery, but they are the output of engineering and dedicated R&D staff working round the clock. Each and every equipment designed & manufactured by us is fruit of continual improvement going at our R&D.

Why our powder recovery booth : The carbon steel powder coated spray chamber with the multi-cyclone recovery gives almost 100 % powder utilization. It is maintenance free and has a very long life. The powder booth is easy to clean, resulting in a quick color change and is safe to operate. No powder spillage out of the booth and maximum recovery through the multi-cyclone results in pollution control.

Velocity of booth should be :

Appropriate enough so that maximum powder should be attracted on the article.

If suction velocity is more, more amount of powder will be sucked towards cyclone & less on article.

If suction velocity is less, then powder will come out from cutout & surroundings will be polluted.

Selection Criteria :

Powder recovery booth :

Multicyclone type of booth consists of a coating chamber, multicyclone with blower, motor & bin. Each part of the booth is designed considering its importance in the system. The purpose of each component is different which should be considered from all angles.

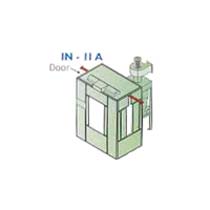

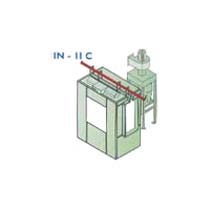

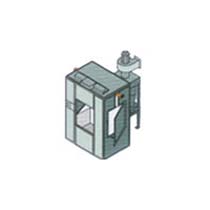

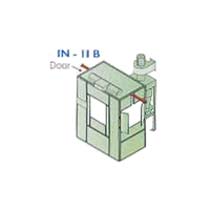

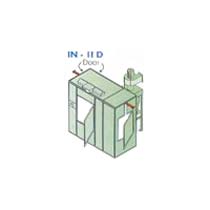

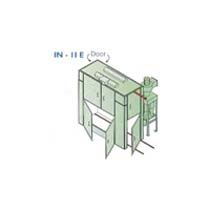

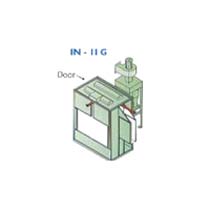

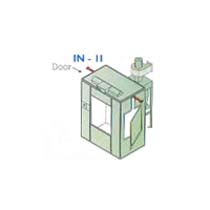

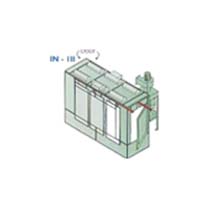

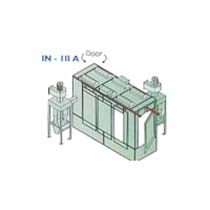

Different Models :

Depending upon size of the article, coating requirements, material handling requirements we have designed some standard models. As a special requirement different customized models are also developed.

| Parameters | Statfield | Other |

|---|---|---|

| Powder sprayed / month. | 500 Kg | 500 Kg |

| Transfer efficiency of gun | 0.7 | 0.5 |

| Powder deposited on article/ month | 350 Kg | 250 Kg |

| Powder in booth/ month | 150 Kg | 250 Kg |

| Recovery Efficiency | 0.98 | 0.85 |

| Powder Recovered / month | 147 Kg | 212.5 Kg |

| Powder Lost/ month | 3 Kg | 37.5Kg |

| Powder lost in terms of Rs/ month(Kg) {@200/Kg} | Rs. 600 / month | Rs. 7500 / month |

| Saving of Powder against others | 82,800/- per year | - |