Listing ID #1409087

Company Information

Ask for more detail from the seller

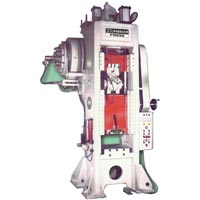

Contact SupplierDCS-Series C Frame Cross Shaft Single Point Power Press uses a welded steel frame, cast iron slide, and over-sized steel bolsters. This enables the press to deliver & ensuring longer die life and higher part quality.

Frame :

Frame is computer aided design aimed at economy and rigidity, welded steel construction, stress-relieved before machining.

Slide :

Cast iron body for lower capacity, fabricated and duly stress -relieved for capacity higher than 80 tons, Six-point /Eight-point type depending upon slide dimensions, eccentricity of loading and press capacity, sufficient long gibbing to maintain excellent parallelism between slide and bed. Liners of bronze casting fixed to gibs with counter sunk screws, easily approachable and replaceable. Slide height adjustment is manual for lower capacity and motorized for higher ones. Slide provided with shear plate jam releasing device or hydraulic device with preset pressure for safety against over loading.

Drive :

Drive Shaft of carbon-alloy steel, ultrasonically tested, random tested for metallurgical properties, ground at bearing surfaces and dynamically balanced for high speed presses. Gears of Cast Steel grade chosen for strength or built up of forged rim and hub with mild steel web, all welded and then stress-relieved, hob cut teeth, hardness matching with requirement, main gear run in oil bath to increase life and reduce noise, bearings of copper-base alloys with holes and grooves for proper lubrication and dissipation of heat.

Fly Wheel :

Fly Wheel of cast iron designed to cater for sufficient energy required for operation, brakes provided on request and mounted on quill for higher capacity, in both cases. Fly wheel is on antifriction bearing.

Pneumatic Cluster & Brake :

We have used Pneumatic Combination Clutch/Brake comprises of a clutch & spring applied Disc Brake which is air actuated. The Clutch/Brakes are intricately designed. These have the twin attributes of high thermal capacity & low air consumption which makes them ideal for high speed, high cyclic, heavy-duty press.

Pneumatic Balancer :

Pneumatic balancers are provided to counter the self -weight of slide (include upper tooling fixed to slide bottom) to help easy slide movement and adjustment.

Lubrication :

Lubrication of all moving/rolling contact surfaces by automatic oil pump and network of pipes tubes flexible pipes manifold and metering cartridge. It is centralized with automatic adjustment timer, can be made circulatory type if required. Lubrication of tooling optional, lubrication network integrated to electrical circuit so that in case of malfunctioning of lubrication system the clutch is detached.

Electricals :

Electrical control panel is provided with a branded PLC & Variable Drive with its supplementary products of Schneider, L&T & Siemens. The Control panel box is generally separated from the frame to suit client's requirement for hassle free functioning. Electrical installation conforms to latest electrical regulations.

All presses may be supplied with the following accessories :

Standard Accessories :

Optional Accessories :

| Capacity at standard stroke 200 Before BDC for Geared Presses100Before BDC for Non-geared Presses |

Tonnes | 25 | 40 | 63 | 100 | 160 | 200 | 250 | 315 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Stroke-standard R fixed Optional | mm mm |

63 80 |

80 125 |

100 160 |

125 160 |

160 180 |

180 200 |

180 200 |

200 225 |

|

| Stroke-Adjustable R | mm | 8-63 | 8-80 | 8-100 | 15-125 | 25-160 | 25-180 | 25-180 | 25-200 | |

| Throat-standard E | mm | 200 | 235 | 280 | 280 | 315 | 450 | 450 | 450 | |

| Shut Height-standard Q | mm | 280 | 255 | 400 | 400 | 425 | 450 | 450 | 500 | |

| Slide Adjustable S | mm | 50 | 63 | 63 | 90 | 100 | 100 | 100 | 125 | |

| Slide Face-Standard GxH | mm | 280X355 | 355X500 | 400X560 | 450X630 | 500X710 | 560X800 | 560X800 | 630X800 | |

| Slide Face Opening P | mm | 40X60 | 50X80 | 50X80 | 50X85 | 63X80 | 63X80 | 63X80 | 63X80 | |

| Distance Between O Upright | mm | 500 | 600 | 700 | 920 | 1000 | 1175 | 1175 | 1175 | |

| Height of Table D Surface from floor | mm | 800 | 800 | 800 | 800 | 900 | 900 | 900 | 900 | |

| Size of Table JxK standard FBxLR | mm | 400X630 | 450X800 | 560X900 | 560X1120 | 630X1250 | 900X1250 | 900X1400 | 900X1400 | |

| Opening in the Table LxMxN FB xLRxDia | mm | 200X250X 250 | 225X280X 280 | 250X315X 315 | 280X355X 355 | 355X450X 450 | 400X630X 560 | 400X630X 560 | 400X630X 630 | |

| Bolster Thickness F | mm | 75 | 80 | 85 | 100 | 100 | 120 | 120 | 150 | |

| Approx.Overall AxBxC size FB xLRxHT | mm | 130X110X 250 | 134X110X 254 | 186X115X 115 | 200X122X 325 | 239X115X 350 | 240X163X 388 | 240X163X 388 | 260X165X 400 | |

| Strokes per Geared Minute Non-geared Mkg | spm | 56 125 | 56 120 | 45 110 | 45 100 | -40 | -31 | -31 | -31 | |

| Flywheel Geared Energy Non-geared Mkg | mkg | 315 160 | 630 315 | 1250 630 | 2500 1250 | -5000 | -8000 | -10000 | -15000 | |

| Motor Geared Non Geared | Kw x rpm | 2.2X1500 2.2X750 | 2.2X1500 2.2X750 | 3.7X1500 3.7X750 | 7.5X1500 75X750 | 11.2X1500 - | 15X1500 - | 18.2X1500 - | 22X1500 - | |

| Approx Geared Weight Non Geared Die Cushion |

Tonnes Tonnes Tonnes |

2.5 2.2 3.15 |

4.5 4.2 5 |

5.5 5.1 8 |

9.5 8.8 11 |

13 - 16 |

18 - 25 |

22 - 40 |

28 - 40 |

|

| Die Cushion | Model | - | HDC 72 | HDDC 82 | HDDC 102 | HDDC 123 | H3DC 144 | H3DC 144 | H3DC 164 | HDC 022-30-125 |

| Force | KN | 17 | 44 | 70 | 100 | 200 | 200 | 270 | 300 | |

| Stroke length | mm | 50 | 50 | 50 | 75 | 100 | 100 | 100 | 100 | |

| Pressure pad area | mm | 290X200 | 335X230 | 380X260 | 475X330 | 535X425 | 600X475 | 600X475 | 85X0520 | |