Listing ID #3934741

Company Information

Ask for more detail from the seller

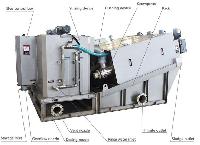

Contact SupplierIncreased market demand for larger and denser bricks have created the need for heavy duty high capacity presses. The latest addition to Hari Machines Ltd. product range includes 800 Ton, Friction Screw Press with complete state-of-the-art technology. With the growth in Refractory Industry to cater to stringent quality requirements of Steel industry,the need for Heavy Duty presses was strongly felt.

In the early 80's Hari Machines Ltd. introduced 400 T Friction Screw Press, indigenously designed and developed for manufacturing large high density refractory bricks. The machine became an instant success with the refractory manufacturers throughout the country. It was an ideal substitute for the imported hydraulic presses because of low capital cost.

Keeping pace with changing trends Hari Machines Ltd. introduced The 800 TON.HSP designed & developed indigenously for the first time in India which was commissioned at O.C.L . India Ltd., Rajgangpur, during Dec 1994 and it is running satisfactorily. Several trials conducted on the press have established that the quality of bricks manufactured in this press is comparable to that of 2000 TON. Hydraulic Press. The press is ideally suited for long size converter bricks (Mag carbons), slide plates & other denser materials.

SALIENT FEATURES

Sturdy Design

The press is closed frame construction consisting of base, head & cloumn rigidly clamped by tie rods

Hydraulic Pre-Compaction

Adjustable pre-compacting strokes are given by hydraulic actuated press slide which can be pre-selected thereby controlling initial compaction of material.

Mould Car System with Floating Mould

Mould box is mounted on 'Floating' table suspended & firmly guided by sturdy springs along with guide rods. Entire assembly moves from ejection centre (located outside press) to pressing centre on a movable trolley which is hydraulic actuated. Trolley is locked at pressing centre during pressing. After completion of pressing trolley is unlocked and moves out to the ejection centre for brick ejection. Material filling to mould is done with the trolley located at the ejection centre. Depending upon the quality and type of brick 'Floating' can be controlled and also floating table can be locked in position if desired.

Vaccum Pressing Arrangement

There is provision of Vacuum pressing arrangement wherein the mould is sealed from top and bottom through rubber diaphram forming a sealed chamber which can expand or contract. The vacuum system, which comprises of a vacuum pump, control valves and tank creates vaccum in the flexible chamber after it has been completely sealed. When the specified degree of vacuum has been achieved,the initial pre-pressing is done hydraulically. The impact bumpings follows through screw spindle which moves independent of the press slide. When the brick gets shaped,air is allowed into the sealed chamber and the rubber diaphram along with press slide is retracted. The entire operation is automatic through PLC.

Adjustable 'Soft' and 'Hard' Impact Strokes

Initial entry speed of the main screw can be preset & controlled for 'SOFT' initial compaction. Subsequent 'HARD' impact strokes are also controlled for intensity and ferquency. This control permits effective deairing during pressing and thus eliminates lamination.

Electronic Brick Thickness Measurment & Display

Provision of brick thickness measurement in the mould and digital readout for Quality Control. Additional display of 'GOOD' & 'REJECTED' bricks based on thickness allowance can be set at the panel.

Charger

Provision of a Pneumatic actuated charger system for filling of material to the mould cavity. Material to be weighed manually & put to charger box. The entire charger operation is automatic.

Centralised Lubrication System

Press is equipped with a powered central lubricating pump adjusted to the required dosing rate which supplies grease to all points of lubrication continuously and sufficiently.

Microprocessor Controlled Press Operation

Single cycle operation of the press is accomplished through PLC. The total number of strokes both 'SOFT' & 'HARD' can be pre-selected. No operator skill is required for pressing since the pressing cycle is intitiated with pushing the 'START' push buttons. Operation is fully consistent avoiding rejection and promoting overall quality.

Colour Monitor & Industrial Keypad for fast & quick entry of Data

For setting required parameters by selecting menu items on the monitor display and thus facilitating control of operation. For display of various fatas including valves status, fault diagnosis and production data etc.

Assured after Sales Service

Hari Machine's Commitment to product excellence & high quality standards is backed by complete inhouse facilities of high quality fabrication, precision machining assembly & testing. The capacity to draw on all its resources to supply high quality machinery and provide technical assistance & after sales service on a continuing basis to its customer has enabled Hari Machines to achieve the reputation of a Reliable Machine Manufacturer. A well equipped Machine shop to handle intricate machining jobs involving high degree of precision. A gamut of Machines including modern NC machines, Heavy lathes, Universal Grinding & Milling Machines etc.