Listing ID #6001872

Company Information

Ask for more detail from the seller

Contact SupplierThe SFXmagnus series operates automatically as well as process and pressure constant. It is suitable for almost every application.

Constant pressure and process consistency-

The SFXmagnus series operates automatically as well as process and pressure constant. It is suitable for almost every application. This series is characterized by an extra large active screen surface area, its compact design, as well as extremely easy operation. Screen changes do not have any influence on the product quality.

The advantages of the SFXmagnus Filtration System

Mode of operation

When a pressure increase upstream of the filter is registered, the filter disk is indexed automatically by means of a pneumatic or hydraulic drive. The active screen area is always kept constant and the pressure upstream of the filter increases only slightly during the whole production process. After the cavities have passed through the melt flow, the screens can be removed without disturbing the production process.

Design

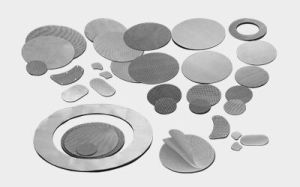

The filter disk – on which the screen cavities are located in a ring pattern – is completely encapsulated by the two filter blocks. Screens can be inserted into the cavities by opening a small hatch door giving access to the cavities. The production process is not disturbed by the screen change procedure. Thanks to the modular design of this filtration system, it is possible to replace the few wearing parts (such as heater elements and bearing bushings) during operation. Continuous production over many years is thus made possible.