Company Information

Ask for more detail from the seller

Contact SupplierFunction:

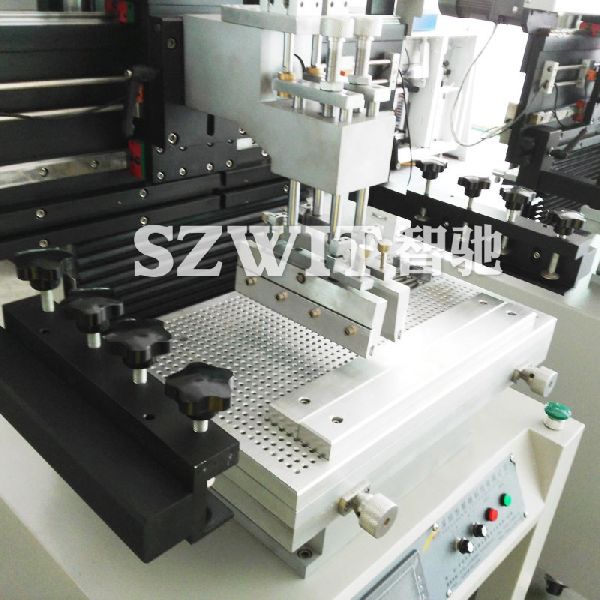

Semi-automatic solder paste printing machine is an equipment to use on SMT production, working principle is to using the stencil to print the solder paste on the specified pad, the good or bad solder paste printing, directly affect the final solder quality.

Features:

1,Using precision guide rail and the Panasonic speed regulating motor to drive the scraper, ensure the printing stability and precision;

2,Printing scraper can be fixed up by rotate 45 degrees is convenient for printing stencil and squeegee cleaning and replacement;

3,Scrapers can be adjusted forward and backward to select suitable position;

4,Combined with a fixed groove printing plates and PIN, easy to installation and adjustment, adapt for single and double sides printing;

5,Calibration by using stencil movement, combined with printed (PCB), X, Y, Z. adjustment, convenient and efficient;

6,PLC + touch screen display, more stable and easy to operate;

7,Single direction, double directions or other kinds of printing methods can be set;

8,Automatic counting function, easy to statistics and arrange production;

9,Adjustable blade angle, steel blade, rubber scraper are suitable;

10,Touch screen with a screen saver function, the time can be adjusted to protect the touch-screen life;

11,Automatic alarm of cleaning the stencil , convenient for cleaning the stencil in time and ensure the printing quality;

12,Using AE unique programming design, easy to adjust printing scraper;

13,Display the printing speed and can be adjusted;

14,A special cylinder is used for lifting up and down to ensure stable operation.

Specification:

Model No | WIT-SP680 | WIT-SP1200 |

Dimension(L×W×H) | L880×W680×H1660mm | L1600×W680×H1750(mm) |

PCB Size(L×W) | 320×450mm | 320×1200mm |

Printing Platform size | 450×320mm | 1250×320mm |

Stencil Frame size | 470×370mm~680×560mm | 470×370mm~1250×550mm |

Printing speed | 0-100mm/sec | |

Power Supply | 220V antiphase 50/60HZ | |

Power Consumption | 100W | |

PCB board thickness | 0.2-3.0mm | |

Fixation of printing position | PCB outer or pin positioning | |

Micro adjust of table board | Front/back±10mm;Right/Left±10mm | |

Printing precise | ±0.02mm | |

Repeated and accuracy ability | ±0.03mm | |

Air Supply | 4-7kg/cm2 | |