Welcome to PJV Valves Private Limited

Manufacturer / Exporter / Supplier / Retailer Of Trunnion Ball Valves, Floating Ball Valves, Bleed Valves, Top Entry Ball Valves, Fully Welded Ball Valves

Welcome to PJV Valves Private Limited

Manufacturer / Exporter / Supplier / Retailer Of Trunnion Ball Valves, Floating Ball Valves, Bleed Valves, Top Entry Ball Valves, Fully Welded Ball Valves

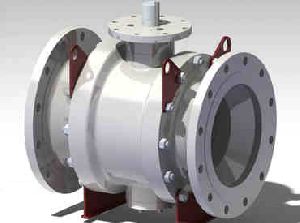

Our trunnion design provides excellent sealing characteristics and long life through our generous approach to corrosion allowances and smart sealing design. Benefits Our trunnion ball valve is designed for excellent sealing performance and longevity. We have worked with many end user specifications to include their requirements in our standard design which means that we are able to manufacture high specification ball valves rapidly. Production Range Sizes : 3/4" upto 24" (Two piece & Three piece construction) Pressure ratings : 150# upto 2500# We manufacture valves in materials ranging from standard Carbon Steel through to exotic alloys such as Super Austenitic st. steel & Inconel. We have developed an extensive supply history in the manufacture of valves in duplex and super duplex st. steel. Design & Manufacturing Standards Our ball valves meet following standards: API 6D, API 608, BS EN ISO 17292, EN 12516-1, 2, ASME B 16.34, ASME B 16.5, 16.10, API 607/ ISO 10497. Design & Construction Features : ✱ Antistatic, Fire safe, Antiblow out stem ✱ Double block and bleed with Self relieving seats. Option of Double piston effect seats available ✱ Body & stem sealing Design Our body & stem seals feature O ring plus graphite as standard rather than O ring or graphite only. Due to our modular sealing design feature, we are able to meet our customers body & stem sealing specifications including lip seals and other sealing options. ✱ Shell Design Our design is built to be suitable as standard for most customer specifications in terms of Shell thickness, corrosion allowance & bolting design requirements. ✱ Sealant Injection Optional sealant injection system for seats as well as stem ✱ Actuation Ready Design Our ISO top mounting designs reduces the time and cost of actuation. Uniform torques provide prolonged cyclic life. ✱ Locking Devices Standard on lever and gear operated valves ✱ Testing We test to API 6D, API 598/EN 12266-1, ISO 5208. Fugitive Emission Testing to ISO-15848-1, 2. Fire safe to API 607/EN ISO 10497/API 6Fa

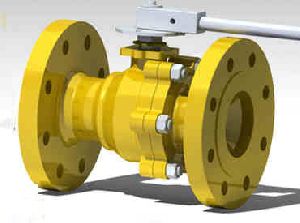

Our Top Entry ball valves design features a generous corrosion allowance and innovative sealing. The products modular design also enables us to manufacture Top entry ball valves according to project specifications. Benefits Our Top Entry ball valve is designed for excellent sealing performance and longevity. We are able to manufacture Top Entry valves to project specifications on a fast track basis due to our smart seating & sealing design. Production Range Sizes : 1/2" upto 8" Pressure ratings : 150# upto 1500# We manufacture valves in materials ranging from standard Carbon Steel through to exotic alloys such as Super Austenitic st. steel & Inconel. We have developed an extensive supply history in the manufacture of valves in duplex and super duplex st. steel. Design & Manufacturing Standards Our ball valves meet following standards: API 6D, API 608, BS EN ISO 17292, EN 12516-1, 2, ASME B 16.34, ASME B 16.5, 16.10, API 607/ ISO 10497. Design Features ✱ Body Sealing Design Our body seals feature O ring plus graphite as standard rather than O ring or graphite only. Our body seal design is modular. We are able to therefore meet our customers body sealing specifications including lip seals and other sealing options. ✱ Stem Sealing Design Our stem design incorporates a tamper proof antistatic device, reduces the friction on the sealing area due to static seal feature. This improves performance and provides a long cycle life as demonstrated by our Fugitive Emissions Testing. The stem design also features live loaded packing and is blowout proof. Variety of stem sealing options viz. O ring, Lip seals, V packing, Cop cone seals etc are available as per customer specifications can be offered in standard design of the valve. ✱ Engineered Seats Compensate for wear and pressures to prolong sealing life. ✱ Shell Design Our design is built to be suitable as standard for most customer specifications in terms of Shell thickness , corrosion allowance & bolting design requirements. ✱ Actuation Ready Design Our ISO top mounting design reduces the time and cost of actuation. Uniform torques provide prolonged cyclic life. ✱ Locking Devices Available on request for lever operated valves & standard on gear operated valves. ✱ Testing We test to API 598/EN 12266-1, ISO 5208. Fugitive Emission Testing to ISO-15848-1, 2. Fire safe to API 607/EN ISO 10497/ API 6Fa.

Share your thoughts with other customers for PJV Valves Private Limited

Add Review