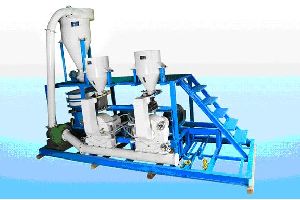

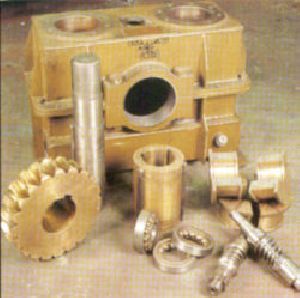

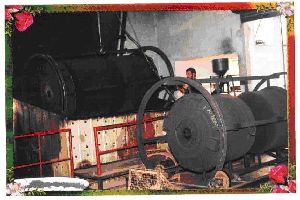

NMEI manufactures plastic granule Pulveriser s which are rugged in design and are proven in performance .The Pulveriser s are made as per the latest technology and under stringent quality control at various stages to ensure that the product once delivered and commissioned gives long lasting trouble free performance with minimum maintenance. NMEI Pulverisers are available in a capacity ranging between 40- 400 kg per hour and are supplied with accessories like hopper loader ( spiral conveyor} for loading granules, electro magnetic feeder for feeding the pulverizes, pneumatic conveying system, cyclone separator, airlock valve, vibrating screen, conveyor for conveying powder etc. as per the requirement of the customer. The main body of the pulveriser is double jacketed with water cooling arrangement and is made of mild steel of suitable heavy thickness. Granules are fed coaxially in a center of the grinding disks where one disk is rotating against a stationery disks. The disks made of EN 19 material are having radically outward expanding grooves with precisely machined groove angle. The disk design is having adjustable gap between two disks and the complete assembly is such that the clogging of the chips or the ground powder is eliminated. This makes the complete system easy to clean, easy to maintain and easy to adjust to any requirement in addition to the production advantage of nearly 150 tones of powder from each set of grinding disks. NMEI Pulverisers can handle granulated materials of low or high density plastic, PVC, PE, PC, LLDPE, and HDPE Outstanding Features of NMEI -Pulvarizers. Latest Technology: NMEI made Pulverisers are manufactured as per latest technology with stringent quality in each and every stage of manufacturing to give you world class quality product in wide range for different applications and rigidly confirming to international standards. Use for LLDPE, HDPE, LDPE, PVC and Delrin and other Synthetic materials. Long Lasting Range: NMEI pulveriser is of high quality sturdy machines which range from 30-500 kgs/ hr., with MAIN BODY DOUBLE JACKETED (WATER COOLED). This will be fabricated out of heavy mild steel of suitable thickness. Bearing Housing: Bearing housing is designed for 5500 RPM with outer double jacketed for water circulation for cool running, OIL lubrication, double ball bearing for higher load bearing, main shaft is dynamically balanced and made from special graded alloy material of tasted quality. The complete design is such that it provides noise less operation and trouble free working. Disk and Mill Body The disk is made from special graded alloy material tested quality and dynamically balanced smooth running. One stationery grinding disk with water jacketed is provided on door frame with provision for easy adjustability of disk gap by set of 4 bolts. Inspection windows (2 Nos) are provided on both side of mill body for visually checking disk gap and assist the gap setting. A large door allows easy access to the Mill body. Several options are available to simplify the cleaning process. Change of disk is very easy and user friendly. Feeding: Feeding hopper is available in Mild Steel or Stainless Steel (optional) with low level indicator which is connected with control panel. Vibrator coil is provided for auto feeding the Mill which is controlled by regulator knob and is connected with control panel for auto tripping in case of overload feeding. Cyclone: Our cyclonic system is well designed for powder separation and easy of cleaning with dust collector cloth for trapping fines. Vibro Screen: Vibro Screen (Gyratory type) is part of our system with suitable size of machine according to model for pulveriser . The Vibro Screen are with specially designed vibro motor, single deck for Mild steel of Stainless Steel (Optional), 20 # S.S. screen with anti blinding ring tray arrangement and basic structure from heavy mild steel for long lasting. Vibro screen recycles the coarse material for optimum output of the Pulveriser. Other Inclusions Complete support structure from heavy steel, Main motor of standard make, high speed blower with motor, Rotary Air Lick value, Pneumatic Hoper Loader (on request). Digital control panel with temperature indicator, overload tripping hopper, if material below low level indicator.