- Brand Nameatlas copco

- MaterialAluminium, Carbon Steel, Cast Iron, Steel

- Automatic GradeManual

- ColorBlack, Blue, Dark Grey, Grey

- ConditionNew

- Power SourceElectric

- PressureMedium Pressure, High Pressure, Low Pressure

- Motor Power0-3Hp, 3-6Hp

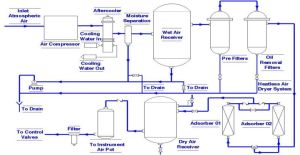

The screw compressor system is very popular due to the many benefits it provides to businesses. Recently, it is possible to come across screw type air compressors in many industrial businesses. Screw type compressors have many differences in terms of operating principle when compared to other compressor models. In other compressor models, the air usually taken from the atmosphere is compressed with the aid of the pistons inside the compressor and components working in synchronization with the pistons. Air is compressed through the gaps created by the reciprocating movement of the pistons. However, screw type air compressors operate based on a system in which rotating screw rotors are in contact with each other. Two screw rotors rotate towards each other and air is sucked in through gaps in the rotor. Then, the gaps in the rotor are narrowed and the air is compressed. This process increases the air pressure and renders it available for use. Screw type air compressors require energy to maintain their operation. Therefore, these compressors require a motor to operate. The motor supplies power to the rotor and makes the rotor rotate. Thus, the air is compressed and pressurized inside the compressor. Screw compressors are frequently used in industrial sectors, particularly in heavy-duty industries that require continuous compressed air. Due to its operating principle, the screw type compressors provide the pressure required by the businesses in the optimum way. As a result, when businesses require compressed air, they can get this air from the screw type compressors without any loss of pressure. Reciprocating compressors are not suitable for heavy-duty industries, both because of their operating principle and because they are not suitable for long-term operation. Screw type compressors provide maximum compression thanks to their rotation between the rotors. As an example. You can compress air at 10 bar 2 times with the help of a reciprocating compressor. However, with the help of a rotary screw type compressor, it is possible to compress air at 10 bar up to 4-5 times. Moreover, it is possible to use this compressed air directly without any loss of pressure.

-is-a-highly-1710132243-7331734.jpeg)

-for-a-1710132243-7331731.jpeg)