Related Category

Business Type

We are well known in the industry as a prominent lathe machine Manufacturer. The Heavy Duty Roll Turning Lathe Machine we export in the international market is manufactured using sophisticated technology and under the stringent supervision of our team of experts. Heavy duty lathe machine is in high demand the more...

We have cordial relations with the logistic companies that allow us to reach any preferred Maharashtra(India) with ease, thus ensuring timely delivery. One of the major concerns of the organization is to make available only quality approved products to the buyers and thus we check the entire range at all stag more...

We are main supplier of this product. more...

Get Quotes from Verified Suppliers

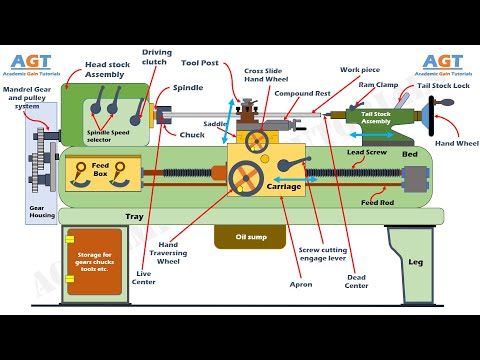

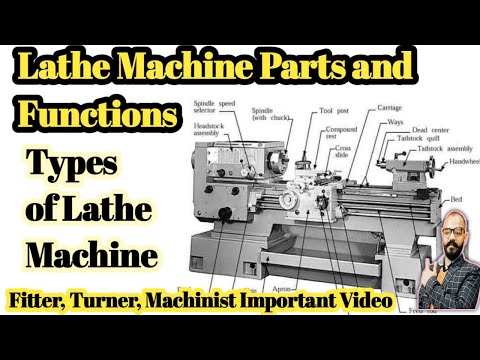

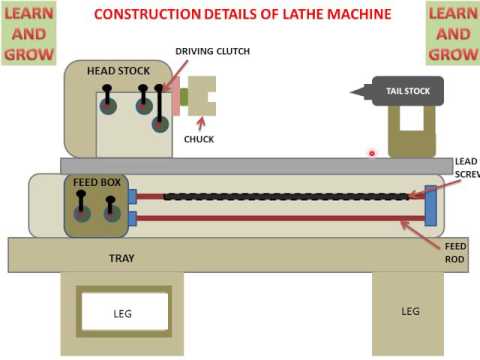

We have lathe machine’s of varying capacity as per diameter, length and load of the job. The machine ranges from minimum 400X1500 mm to 700X4800 mm. Maximum capacity of chuck to hold the job in diameter is 800mm. Simultaneously we can perform belt grinding operation too. We also have an all gear machine. Ma more...

Light duty lathe machine 1370 MM., 1600 MM, & 1830 MM, Height of Centre 165 mm, Swing Over Bed 325 mm, Movement of Cross Slide 225 mm, Swing of Gap 500 mm, Length of Gap in Front of Face Plate 125 mm, Spindle Bore 40 mm.All The above specifications are approximate and subject to change without prior notice as more...

Banking upon in-depth domain knowledge and years of vast experience, we are engaged in manufacturing and supplying CNC Automatic Lathe Pipe Cutting Machine . This machine is suitable for precision cutting and beveling of all pipes made of ferrous or non ferrous materials. To manufacture this machine, we use more...

Features: Equipped with Hiwin brand linear motion guideway. It ensures the fast rapid traverse and maintenance free which is very important for mass production Ballscrew are pre-tensioned assembly. Servo X/Z axis motor spindle is completed with frequency inverter motor or servo motor. Variable configura more...

Standard Eqipment : 1) Chuck Plate 10” 2) Spindle Sleeve 3) Dead Centre 4) Toolpost Key 5) Change Gear Set Extra Payable Equipment : 1) Face Plate 2) Steady Rest 3) Follow Rest 4) Rear Tool Post Key 5) Electricals 6) Norton Gear Box 7) Coolant Pump Tank 8) Machine Lamp 9) Throgh Chuck 10) Dog Chuck 11) more...

Crankshaft will be loaded in the fixture. Clamped by hydraulic operated jaws. Precision spindle unit is mounted on two Z servo slides. Fixture is mounted on servo operated Y slide. Std. Special tooling arrangement is provided. Facing cutter after rework is located on special adaptor. On special adaptor collet more...