Welcome to Labour Craft Private Limited

Manufacturer / Exporter / Supplier / Retailer Of Industial Splitting Band Knives, Leather Fleshing Blade, splitting band knives, Grinding Stone, Leather Shaving Blades

Welcome to Labour Craft Private Limited

Manufacturer / Exporter / Supplier / Retailer Of Industial Splitting Band Knives, Leather Fleshing Blade, splitting band knives, Grinding Stone, Leather Shaving Blades

Leather Fleshing Blades are primarily used in tanneries for processing of raw hides. These blades although look alike its counterparts, Leather Shaving Blades, differ in functionality and specification. Labourcraft has been manufacturing them since its inception in 1954. It is the first company in India manufacturing these Spiral Blades for processing of raw hides. With over 60 years of experience in this field of fabrication, the Leather Fleshing Blades ensure complete customer satisfaction and adhere to all standards of quality. Leather Fleshing Blades are manufactured by a team of technically sound and experienced professionals with the aid of automated computer controlled machinery. It helps to maintain the quality of precious hides and skins. Consistency has always been our motto and excellence is our goal; with an honest effort to turn the dreams of our customers to reality. Total Working Width: Fleshing Blades are manufactured for total working width of fleshing machines from 1200mm to 3300mm. Pitch and Inner Diameter: Pitch and Inner Diameter of the blade depends on the cylinder specification specified by the original or refurbished machine manufacturers. Thickness: The blades are manufactured in thickness ranging from 2.2mm to 2.8mm. The thickness is more at the inside of the helical spirals than at the outside for a better cutting action. Blades for fleshing sole leather or belt leather have higher thickness than blades used to flesh leather for the manufacture of leather goods. Hardness: The blades manufactured by Labourcraft have a uniform Rockwell Hardness of 63 HRC. However, the hardness of the blades at the inside of the helical spirals is much less compared to the hardness of the same blades at the outside. It ensures ease of fitting and removal during the process of blade changing or reblading.

GRINDING WHEELS and BLOCKS supplied only along with our knives, are used in large number of tanneries around the world. The wheels and blocks are known for their consistency, quality, vibration-free run, optimum hardness and perfect edge creating ability. Variation in the manufacturing process helped us to develop Vitrified or Resin Bonded Grinding Wheels or Blocks. Their usage and recommendation is based on application and result. Total Working Width of GRINDING WHEELS and BLOCKS vary in sizes depending on the machine for which they are used. Pitch and Diameter of the Stone are Extensive quality checks, right from choosing of the raw material to the fabrication of the finished product, ensure that the wheels and blocks strictly adhere to standards that help to develop the perfect edge.

Leather Shaving Blades, Manufactured from steel with customised alloy specification, find its way to a large number of tanneries around the globe. Special processes of heat treatment and formation of steel provide optimum hardness, lowest tolerance and longer knife life. Extensive in-house quality checks reinstates the quality of the blades. Variances in manufacturing process has helped to develop Full Hard, Centre Soft and Front Hard Blades. Their recommendation and usage depends on the type of leather, tanning process of hides and thickness of skins. Total Working Width rages from 300mm to 3200mm. Pitch and Diameter of the Blades depends on the cylinder specification of the original or refurbished machine manufacturers. Thickness ranges from 1.8mm to 2.2mm. The thickness is more at the bottom for a better cutting action. The blades have a uniformRockwell Hardness of 62 HRC. However, the hardness of the blades near its inner diameter is much less. It ensures ease of removal during the process of blade changing or reblading.

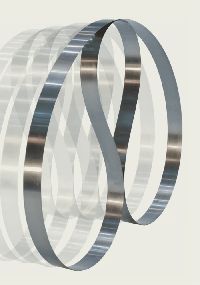

Splitting Band Knives are extensively used in tanneries, footwear, leather goods, paper, foam, rubber, cork, laminates, textiles and several other industries. 60 years of experience in this field helped us in fabricating blades of the highest quality ensuring absolute customer satisfaction. These blades are also referred to as Splitting Knives or Bandknives. Bandknives are manufactured from steel with customized composition and specification. Only the best steel from renowned Swedish manufacturers are used to fabricate these blades. The entire procedure ensures consistent quality, optimum hardness, zero vibration, lowest tolerance and longer knife life. Pre and post sale services coupled with wide distribution network helped us to handle logistics with ease. Intense focus on customer satisfaction and co-operation with machine manufacturers has helped us to fabricate blades that meet the highest standards of quality. The quality of Splitting Band Knives is never compromised. The blades are processed with the help of technically sound professionals, automated machines and technical knowhow developed over the years. It has further helped us to develop and deliver Splitting Band Knives at most competitive prices. Consistency has always been our motto and excellence is our goal; with an honest effort to turn the dreams of our customers to reality. The length (also referred as circumference) of the blades vary from 2000mm to 14000mm. The tolerance along the length for the blades manufactured is +- 10mm. The width of Splitting Band Knives manufactured by Labourcraft vary from 8mm to 100mm. The tolerance along the width for the blades manufactured is +- 2mm. The blades have a uniform Rockwell Hardness of 46 +- 1 HRC. The tolerance along the length is 1mm, along the width is 0.1mm and along the thickness tolerance is 0.01mm.

Share your thoughts with other customers for Labour Craft Private Limited

Add Review