Welcome to Isel

Manufacturer / Exporter / Supplier / Retailer Of industrial fan, intake silencers, duct silencers, backward curved impeller, fan silencers

Welcome to Isel

Manufacturer / Exporter / Supplier / Retailer Of industrial fan, intake silencers, duct silencers, backward curved impeller, fan silencers

ISEL manufactures silencers for airgas applications. The silencers are designed knowing the application, noise level and noise spectrum. In order to have the basic data input for design-noise level measurements are carried out under normal load conditions, full load conditions and also with damper closed conditions. The measurements are carried out at number of locations at fan inlet and at distances of 1 or 2 or 3 metres. The noise contour at number of octave frequency bands are plotted and the Silencer is designed on the following considerations. - The source noise level at fan inlet under full load conditions shall be brought down nearer to NC80 Curve by suitable combination of acoustic systems. - The pressure loss across the silencer shall be around 25 mm wcl.

ISEL manufactures silencers for airgas applications. The silencers are designed knowing the application, noise level and noise spectrum. In order to have the basic data input for design-noise level measurements are carried out under normal load conditions, full load conditions and also with damper closed conditions. The measurements are carried out at number of locations at fan inlet and at distances of 1 or 2 or 3 metres. The noise contour at number of octave frequency bands are plotted and the Silencer is designed on the following considerations. - The source noise level at fan inlet under full load conditions shall be brought down nearer to NC80 Curve by suitable combination of acoustic systems. - The pressure loss across the silencer shall be around 25 mm wcl.

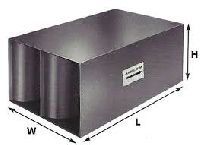

In order to have the basic data input for design-noise level measurements are carried out under normal load conditions, full load conditions and also with damper closed conditions. The measurements are carried out at number of locations at fan inlet and at distances of 1 or 2 or 3 metres. The noise contour at number of octave frequency bands are plotted and the Silencer is designed on the following considerations. - The source noise level at fan inlet under full load conditions shall be brought down nearer to NC80 Curve by suitable combination of acoustic systems. - The pressure loss across the silencer shall be around 25 mm wcl. The selected combination of acoustic systems may consist of any one or a combination of two or three components. Multiple duct baffles with acoustic material of resin bonded fibre glass mineral wool supported inside perforated sheets at fan inlet. Alternatively circular central core intake Silencer with centre core , baffle supports and housing, lined with mineral wool inside the perforated sheet. Outlet Silencer- baffle type or Centre core type Sound insulation with mineral wool inside perforated sheets in the scroll portion of the casing , inlet duct , suction Chamber and outlet duct Coating of all the fan parts in flow area with sound insulation material. For improved noise insulation a fan enclosure with silencer lining and weather protection

Backward curved with aerofoil blades Backward curved laminar blades Forward curved blades Forward curved radial tipped blades Radial blades Paddle type blades

Share your thoughts with other customers for Isel

Add Review