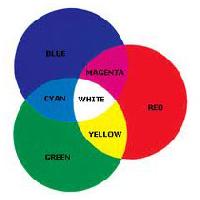

we are a well-known manufacturer, exporter and supplier of liquid colorant in india and bangladesh. Our liquid colorants are viscous and free-flowing dispersions of pigments in polymer-compatible carriers. Basically, liquid colorant and additives are highly concentrated dispersions of pigments, dyestuffs and other coloring materials. They are also chemical additives for plastics, in an almost universally compatible liquid carrier system. Our liquid colorants and additives blend quickly with the plastic granulate or powder, producing a homogenous mass, which becomes an integral part of the polymer matrix. This mass when plasticated gives much more uniform dispersion that can normally be achieved with dry pigments or master batches. Our liquid colorant gives excellent cost-benefits as compared to traditionally used coloring methods. special feature : loading percentage in lower homogeneous mixing product range : standard metallic glitter transparent fluorescent pearl effect pearl luster luminescent transparent pet custom made shades applications : consumer durables automobile components records & cds medical components cosmetic packaging packaging film toys sports goods flooring systems footwear cables stationary articles tapes and fibers food packaging blow molded containers pu and pu foams liquid additives : antioxidants lubricants pigment dispersers stabiliser uv absorbers heat stabilizer others : colorkleen (screw cleaner) colorsperse (pigment disperser) advantages of using colortek product : colortek systems eliminate dust problems resulting in safer and cleaner work places. uniform and good dispersions due to finer particles of pigments (below 5 microns). colortek colorants and additives should ideally be dosed on–line with the help of the systems. However, it is perfectly feasible to use them by the conventional tumble-mixing process. colormatic dosing pumps have been developed using advance integrated microcircuit techniques, to provide a reliable, simple and highly accurate means of metering. The colorant or additive is not in direct contact with the puphead. Control of addition rates by the dosing pump throughout production offers accurate repetition of colors from one run to another. Preblending is also eliminated. Metering eliminates color contamination of machines and hoppers enabling rapid, easy change-over within polymers, colors, additives and reduces wastages. greater depth and brightness of colors with uniform dispersion is also possible with very low usage of liquid colorant. The usage norms vary between 0.1 to 2% but generally it is 0.5 – 0.8%. There is no adverse effect on the physical properties of polymers. colortek products are water miscible, thus allow fast and easy cleaning. No adherence to metal parts takes place and plate out is eliminated. Purging times are much shorter and wastage is also less. Due to the lubricity of the carrier systems, screw wear is materially reduced. In extrusion operations, screen changes are required less frequently. cycle time is reduced in injection molding and extruder output is increased because of the improved flow properties imparted by colortek products to most of polymers. Mould can be filled faster and easily without the need for high melt temperatures of high pressures. This reduces wear and tear of processing equipment and results in products with improved finish and performance due to lower heat histories during processing. polymer scrap containing colortek products can be regranulated and reprocessed as usual. Multicolor scrap can be over colored using suitable colortek colorants. faster and accurate color matching for any polymer can be supplied from few grams of trial runs to 500 kgs per batch. colortek products have long term storage capabilities at normal temperatures. They are nonvolatile, non-flammable and non – toxic. The colortek system can be set up on the machines within 15 minutes. Our technical staff helps with installations training and technical back-up, whenever required. Spillage and clean up can be easily accomplished using a solution of detergent and water. any number of customized shades can be made on request. Computerized color matching provides the client with unsurpassed color quality and matching. colortek product enables direct saving, in terms of lower coloring costs, increasing color uniformity and minimizing adverse effect on physical properties. Indirect cost saving also result from lower inventories, shorter production cycle, increased yield lower housekeeping costs, etc. all colortek products are heavy metal free and meet the regulations for export to almost every country in the world. cost advantages : the usage norms of colortek products vary between 0.1 to 2.0 % but generally it is 0.5 to 1.0 %. Direct costs saving of 10-25 % is possible with our liquid colorant, because of this lower usage norm than polymer base master batches. Many other indirect cost saving is possible, which must be taken into account. Some of them are as follows- with the metering unit, preblending or tumble –mixing can be eliminated. multi-handling of the polymer can be reduced, resulting in less wastage of expensive materials. overall cleanliness of operation requires less housekeeping efforts. lesser inventories as there is no need to stock multiplicity of master batches or concentrates. increased output per unit time by improved production cycle. color use can be minimized with less polymer wastage and lower scarp rates. compatibility : colortek products are compatible with almost all major polymers, including engineering plastics and most filled polymers viz. Ldpe, pu, lldpe, hdpe, ps, pp, abs, san, pc, pps, pom, pmma, pvc, eva, ca, polymers, pet, pbt etc. They are also suitable for production of rigid flexible structural foams and plastisol systems. thermal stability : colortek liquid carrier is stable up to around 320oc. This means it can be used in almost all polymer conversion as well as post-finishing processes.