Welcome to Axzact Consultancy & Services Private Limited

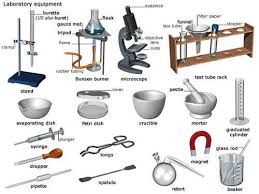

We started our organisation in the year 2003 by a group of dedicated engineers. The promoters have the experience of more than twenty years on cnc machine tools technology & various types of process controls in different industries. We are working in the field of complete technology solution in turn-key basis to serve the engineering industries in the areas of • productivity improvement in the areas of machining, fabrication and assembling. • process automation using mechatronics, plc, cnc, scada solutions. • machine tool calibration. • supply of critical & import substitute spares for machine tools. • supply of precision components. Design, manufacture and supply of special purpose machines/ tools/ and accessories/ jigs/ fixtures/ measuring instruments. • fabrication of special laboratory and research equipments/ setups. • supply of workshop machinery and laboratory equipments. Our design and project division is located at bhubaneswar and we have our workshop at b/6, industrial area, rourkela, where we have machining/ fabrication/ assembling facility for small to medium type equipments. our team of engineers study particular requirement of the user and then we provide the solution in form of a complete proposal based on the preliminary design. On getting customer’s order, we design the process, automation, equipment or accessories as the case may be. We then get the components/ sub assemblies manufactured at our works or by our approved vendor under our strict supervision and inspection. The final assembly is done by us at our rourkela works. For assembling over size jobs, we use our vendors shed for final assembly. So far we have been major vendor of m/s larsen and toubro limited, kansbahal works. We have already executed numerous jobs for them. Please find under few of these jobs. 1.design, manufacture and supply of 10 spindle drilling unit. 2.white metal bearing pads for grinding machine. 3.repair and refurbishing of angular and universal milling heads. 4.repair of pneumatic index tables. 5.calibration of late machine 6.development of machining process including jigs, fixtures & special measuring instruments for blade adaptor for m/s batal industries, 7.retrofitting one two axis slide of facing lathe to cnc radius profile cutting machine for drying cylinders. 8.design, mfg. & supply of multispindle drilling machine for drilling holes in duo-stabilizer rolls. 9.making of one plc controlled automatic pressure testing rig for drying cylinders. 10.design, mfg. & supply of medium to heavy duty roller steady rests for center lathes and facing lathes. 11.heavy duty support rollers for facing lathe (safop)

-

Year of Establishment

2003

-

Primary Business

Retailer

-

Number of Employees

20 - 50