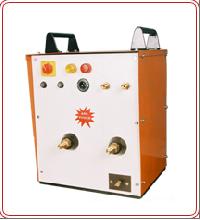

Process In Tungston Inert Gas Welding (GTAW) process, the arc is formed between a non consumable electrode and the work piece. The arc is shielded by inert gas such as Argon or Helium to avoid oxidation. A filler metal may be used depending upon job requirements. The equipment for TIG consists of: A drooping potential DC Power source. HF Control unit Set of Accessories like Welding cables, Torch, Regulator, Flowmeter, Gas hose etc. Advantages of the process: Intense source of heat Welds are very clean and smooth. Hence cost of finishing reduced. Ideally suited for welding of thin gauges. Suitable for almost all metals. Application: Welding of Stainless steel, Carbon steels, Copper, Aluminium and its alloys. It is commonly used for Dairy equipments, Solar equipments, Heat exchangers, Steel furniture etc. ARC POWER make TIG units are availbale with or without power sources in the range of 200 A to 400 A either Gas cooled or Water cooled.