Welcome to Amar Plastic Works

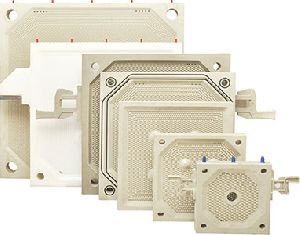

Manufacturer / Exporter / Supplier / Retailer Of Buckles, Filter Plate, Automatic Filter Press, Fancy Clips, Fancy Buckles, Silver Pin, Pearl Pin, Fancy Buttons, Clips, Chatons, Filter Press

Welcome to Amar Plastic Works

Manufacturer / Exporter / Supplier / Retailer Of Buckles, Filter Plate, Automatic Filter Press, Fancy Clips, Fancy Buckles, Silver Pin, Pearl Pin, Fancy Buttons, Clips, Chatons, Filter Press

The Recessed plate frame is however integrated within the Recessed filter plate thus significantly enhancing the plate’s stability. This enables Recessed filter plates to be used at much higher filtration pressure levels. Optional cake and plate thicknesses are available depending on the specific filtration conditions and application. The Recessed filter plates are made of polypropylene and feature excellent chemical resistance and simple in handling. The Recessed Plate Filter Press will compact sludges to a dry cake with a density that is dependent upon the ultimate compaction pressure and the characteristics of the particular sludge.

The function of the plate shifter is to move the plates and allow rapid discharge of the filter cakes accumulated in between the plates. It also contains a diaphragm compressor in the filter plates which aids in optimizing the operating condition by further drying the filter cakes. Automatic Filter Press An automatic filter press has the same concept as the manual filter and frame filter, except that the whole process is fully automated. It consists of larger plates with mechanical “plate shifters

A standard filter press application for metal hydroxide sludge, for example, with plates that provide a 32mm cake thickness generally takes about 4 hours to fill. The unit is usually 80% full at about the 2 hour mark. Due to the high pressure (100 psi from the diaphragm pump being counteracted by the 4, 000 psi of hydraulic pressure), resistance builds and the diaphragm pump begins to slow down considerably.The safest way to inflate the membranes is to use water instead of air. If you are using air to inflate the membrane and you experience a tear, you run the risk of plastic breaking which can be extremely hazardous. However, if you use water and experience a rupture, you may end up with a water leak, which is much safer and easier to contain. A tank and pump are used to fill the membranes with water via the manifold piping which would be stainless, PVC or steel (depending on the application) and flexible tubing to connect the manifold to the plates. The water pumps into the membranes during the squeeze process and once that is complete, it is drawn back to the water tank for reuse.

Share your thoughts with other customers for Amar Plastic Works

Add Review